❙ Introduction

Features:

1. It is mainly used for semiconductor packaging and testing, washing the front end of the line body, and transferring the board to the lower computer equipment through the storage method of the clip frame, with automatic feeding function.

2. The control system adopts PLC control.

3. The operation interface adopts touch screen.

4. Lifting and translation are controlled by servo motor, and the lifting and shifting distance can be set arbitrarily.

5. The board feeding method adopts the stepper motor method.

6. The frame changing method adopts the platform multi-frame storage method, which has the function of single-frame

feeding and multi-frame feeding at the same time.

7. The positioning method of the mechanical card-type bin can be adjusted arbitrarily for bins of different sizes. 8. Equipped with standard SMEMA communication port, which can communicate with other automation equipment.

Advanced Loader & UnLoader

| Model | I.C.T-BLD600 | I.C.T-BUL600 |

| Board size (mm) | 80*50~330*120 | 80*50~330*120 |

| Transmission height (mm) | 900±20 |

900±20 |

| PCB Loading time | 6-16 sec | 6-16 sec |

| Magazine size | 80*50*100-300*150*400 | 80*50*100-300*150*400 |

| PCB thickness | 0.2-2.0mm | 0.2-2.0mm |

| Transmission direction | L to R/R to L | L to R/R to L |

| Compressed air pressure | 0.4~0.6Mpa | 0.4~0.6Mpa |

| Power | AC220V±10V, 50/60HZ 450W | AC220V±10V, 50/60HZ 450W |

| Machine size | 1000х1100х1300 mm | 1000х1100х1300 mm |

| Machine weight | 245KG | 245KG |

❙ Company Profile

I.C.T is a manufacturer of SMT machines. It mainly provides customers with SMT Production Line including SMT Stencil Printer, Pick and place machine, Reflow Oven, SMT AOI Machine, Wave Soldering Machine and PCB Handling Machine etc.

I.C.T has more than 25 researches on SMT and DIP technology, for the world Customers provide SMT total solutions. There are successful cases of SMT technical team in Asia, Europe, America, Africa, and Australia.

I.C.T provide SMT solutions at various stages according to the different needs of customers. I.C.T is not only a provider of SMT equipment and technology, but also is the customer's escort in the field of SMT and DIP.

Successful Experience:

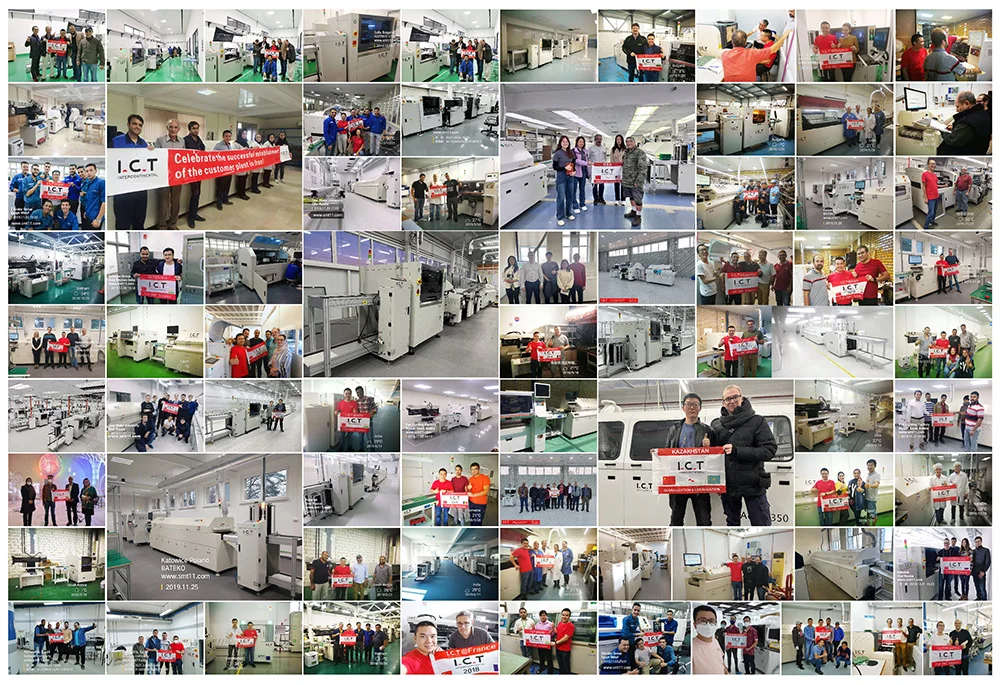

I.C.T's Customer In 35 Countries Around the World

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

Click Here Get More Informaion!

❙ I.C.T SMT Machine Exhibition

❙ I.C.T Global Service

❙ FAQ

A: Leading SMT Supplier in China; Trade assurance to USD 560,000+; Professional after-sales service team.

Welcome more people to discuss with us about SMT technologies and solutions, please Contact Us for more information:

Tel: +86 13670124230 (WhatsApp/Skype/WeChat), Email: info@smt11.com / etasmt@foxmail.com