High Quality BGA Rework Station

❙ Introduce of BGA Rework Station

1. The upper and lower hot air heating,which can heat up at the same time from the top of he component to the bottom of the PCB;bottom IR heating,temperature precision control within ±1°C.8 segment temperature control independently.

2. Hot air district heating for BGA and PCB at the same time,and large area IR heater preheating up for the bottom of PCB to avoid completely PCB deformation during reworking,the upper or lower temperature zones could be used alone and combine freely the energy of up and lower heating element.

3. Adopted high precision K-type thermocouple close-loop control and PID parameter self-setting system.

4. temperature curves can be displayed with instant curve analysis function and multi-group user data can be saved;temperature can be tested precisely through external measurement interface,curves can be analysed、set and correct on the touch screen at any time.

❙ Specification of BGA Rework Station

| Power supply |

AC 220V±10% 50/60Hz |

| Total power |

Max 5300W |

| Heater power |

Upper temp.zone 1200W,second temp.zone 1200W,IR temp.zone 2700W |

| Electrical material |

Driving motor+PLC smart temp.controller+color touch screen |

| Temperature controlling |

high precision K-sensor,Closed Loop,independent temp.controller,the precision can reach ±1°C |

| Locating way |

V shape slot,PCB support jigs can adjust,laser light do fast centering and position |

| PCB size |

Min 10×10 mm--Max 450×390mm |

| Applicable chips |

Min 1×1 mm--Max 80×80mm |

| Overall dimension |

L650×W630×H850mm |

| Temperature Interface |

1 pcs |

| Weight of machine |

65 Kg |

Click Here Get More Informaion!

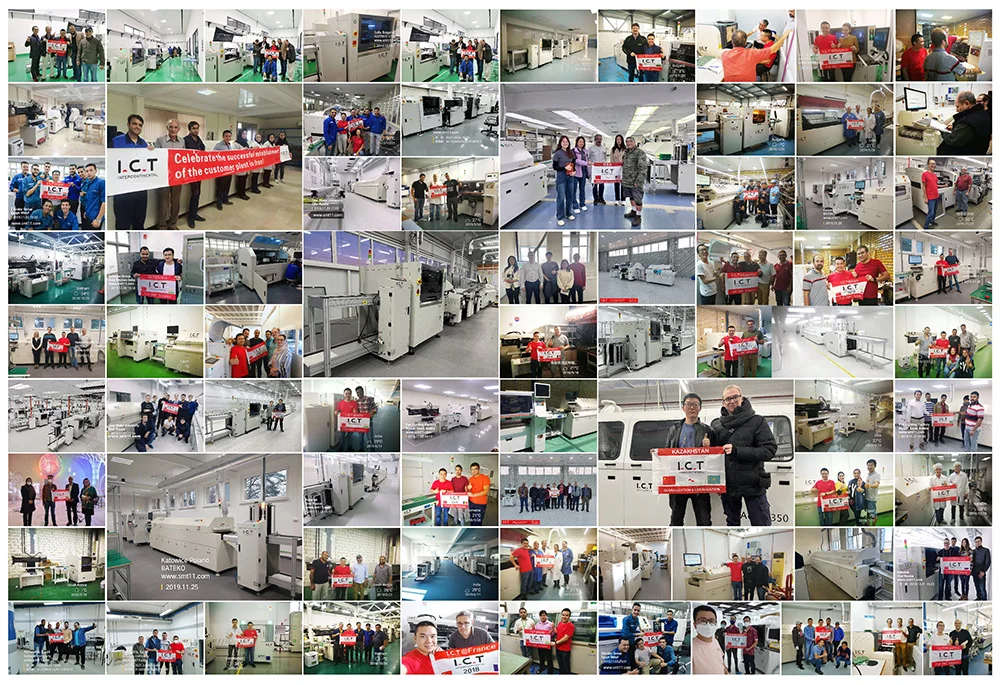

❙ I.C.T Customer Factory

❙ Company Profile

I.C.T is a manufacturer of SMT machines. It mainly provides customers with SMT Production Line including SMT Stencil Printer, Pick and place machine, Reflow Oven, SMT AOI Machine, Wave Soldering Machine and PCB Handling Machine etc.

I.C.T has more than 25 researches on SMT and DIP technology, for the world Customers provide SMT total solutions. There are successful cases of SMT technical team in Asia, Europe, America, Africa, and Australia.

I.C.T provide SMT solutions at various stages according to the different needs of customers. I.C.T is not only a provider of SMT equipment and technology, but also is the customer's escort in the field of SMT and DIP.

Successful Experience:

I.C.T's Customer In 35 Countries Around the World

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

Click Here Get More Informaion!

❙ I.C.T SMT Machine Exhibition

❙ I.C.T Global Service

Welcome more people to discuss with us about SMT technologies and solutions, please Contact Us for more information:

Tel: +86 13670124230 (WhatsApp/Skype/WeChat), Email: info@smt11.com / etasmt@foxmail.com