The Programming System is a highly efficient, fully automated, intelligent IC programming machine designed for the production of large quantities of electronic products. each module is completely independent, programming speed is fast and efficiency is much higher than parallel mass production programmers. The system design modules are optimised for short project switching times and high reliability.

3. Each axis has a limit sensor, and the software sets the limit position to ensure maximum machine safety.

5. Can be compatible with customers' own programming adapters according to usage requirements.

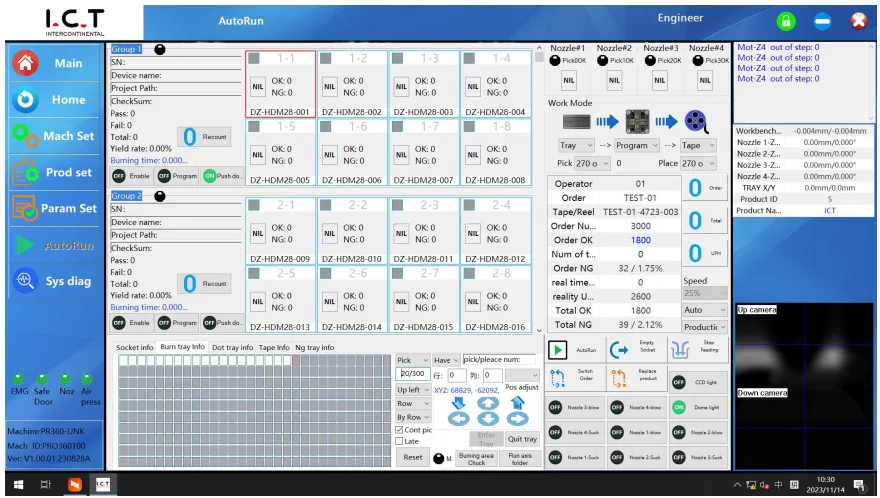

1. The all-English interface meets international needs, and the software is easy to learn and operate;

| Item | Mode | I.C.T-910 |

| Transmission system | Efficiency of the machine |

Standard machine:

Equipped with universal burner of Puro and other brands: 8 sets of 32-64sit

burners: UPH 2000-3000PCS/H;

Equipped with 204AP brand universal burner: 3 sets of 12sit burners:

UPH1600-2200PCS/H

|

|

A small number of diverse modes: equipped with 3 sets of 204A burners, UPH

1600-1800PCS/H.

|

||

|

Packaging conversion mode: pallet to tape production capacity of 4000PCS/H

(12mm tape products as an example)

|

||

|

Control precision

|

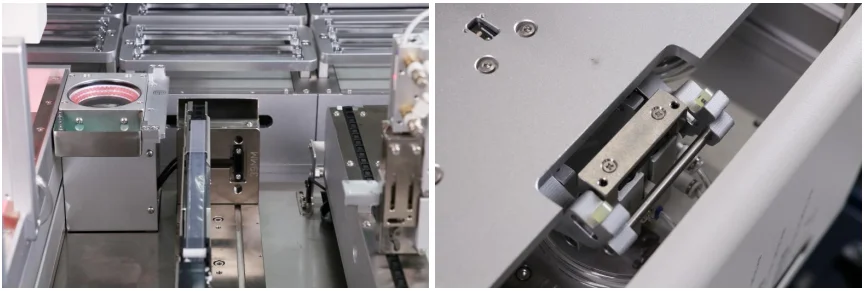

Precision servo screw drive, accuracy: X-axis ±0.015mm; Y-axis ±0.015mm; Z-axis

±0.03mm; P-axis ±0.03mm; U(θ)-axis ±0.15°

|

|

|

Suitable package form

|

PLCC, JLCC , SOIC, QFP, TQFP, PQFP, VQFP, TSOP, SOP, TSOPII, PSOP, TSSOP, SON,

EBGA, FBGA, VFBGA, BGA, CSP, SCSP, and so on. (Open Top adapters, some ICs

need to be customized with special adapter consumables).

|

|

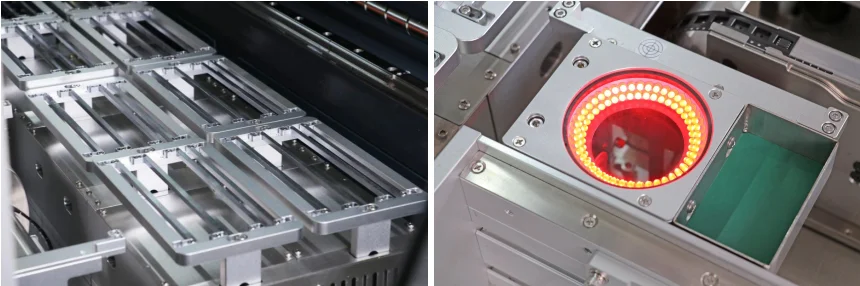

| Includes precision upper and bottom CCD positioning system. | ||