SMT Conformal Coating UV Conveyor for PCBA Coating Line

❙ Introduce of PCBA Coating Line Machine

PCBA Coating Machine:

Good quality PCBA conformal coating line, SMT coating line equipment, with high precision and best price.

1.PLC control, windows operation, fault acousto-optic alarm and menu display.

2.Continuous surface spraying, automatic detecting initial distance and coated width.

3.Servo motor reciprocating coating, can be arbitrary set about PCB before and after the offset.Special aluminum alloy orbit and stainless steel conveyor chain.

4.Equipped with a fan-shaped spray glue valve, can be automatically.

5.Rubber valve automatically soak, to prevent clogging.

6.Inlet and outlet are equipped with communication socket, can online connection with other machines.

7.Independent paint container barrels

8.Equipped with exhaust gas collection, outfalls.

PCBA Coating Loader &Unloader:

1.Strong, firm and stable design.

2.'soft touch' LED control panel or touch screen can be selected.

3.Top&bottom pneumatic clamps to secure magazine rack.

4.No PCBA breakage guaranty because of special gas circuit design.

5.Automatical diagnosing fault code display function.

6.Wear-resistant cable and have long service life.

7.Compatible SMEMA interface.

PCBA Coating Conveyor:

1.Modular design, optional assembly as per client’s requirement.

2.Rugged steel design, improves equipment stability .

3.Smooth stainless steel screw to adjust the width of the rail.

4.Variable speed control.

5.Circuit board testing mode.

6.Using a dedicated aluminum slot for transfer orbit to prevent PCB stuck.

7.Heavier bottom design, not easily shift.

PCBA Coating IR Oven:

1. Control system:Instrument or plc+touch screen or PC control optional, make sure machine working steadily.

2. IR heating: top zones IR heating, good heater compensatory,High thermal efficiency, energy saving, speedy heating.

3. PID intelligent precision controller, automatically control heating volume, fuzzy control function changes the external heating fast, and by internal control ensures more balanced temperature.

4.Use imported big current solid relay, without touch point output, safe, reliable, with special SSR radiator, greatly improve thermal efficiency and lifetime.

5.I.C.T using third-party over-temperature protection, multiple layers protection to ensure safe operation.

6.Products comply with CE,CCC,UL and other standard or specifications.

7.Independent cooling area ensures the low temperature when PCB comes out.

UV Curing Oven:

1. Control system:Instrument or PLC+touch screen control, make sure machine working steadily.

2. UV lamp lifetime can reach 1000-1200 hour, the energy of UV is higher and the penetration ability of the coating is stronger. abnormal lamp protection device.

3. Conveyor belt made by Teflon materials, has no pole speed regulation, and speed is stable and adjustable.

4. Focus design, import high light reflector lamp shade, instant drying, fast speed..

5. Independent cooling area ensures the low temperature when PCB comes out.

6. Transmission system use imported motors, speed adjuster, smoothly running, adjustable speed at 0-2000mm/min.

7. Stainless steel chain transportation, the effective width is 50-450mm, the width can be adjusted.

❙ Specification of PCBA Coating Line Machine

| PCBA Coating Machine | |||||

| Model | I.C.T T500 | I.C.TT550 | I.C.T T550U | I.C.T T600 | I.C.T T650 |

| Nozzle Number |

1 | 2(atomization valve 1head, precision valve 1head) |

2(atomization valve 1head, precision valve 1head) |

2 (atomization valve 2head) |

3 (atomization valve 2head, precision valve 2head) |

| PCB Size(mm) |

50*50 ~ 450*450 |

50*50 ~ 450*450 |

50*50 ~ 450*450 |

50*50 ~ 450*450 |

50*50 ~ 450*450 |

| Transport Height |

900±20mm |

||||

| Max. Speed |

400mm/sec |

||||

| Dimension(mm) |

L1100*W1300*H1700 |

||||

| Weight |

Approx:750kg |

||||

| PCBA Coating Loader & Unloader | |||||

| Model | CLD |

UCLD |

|||

| Control System |

PLC | ||||

| Transport Height |

900±20mm(or Customer Specified) |

||||

| Communication |

SMEMA for Both In & Out |

||||

| PCB Size(mm) |

50*50-450*450 |

||||

| Dimension(mm) |

850*865*1250 |

||||

| PCBA Coating Conveyor | |||||

| Model | Conveyor |

UC-1000(UV Inspection Conveyor) |

SC-1000(Seal UV Conveyor) |

||

| Rail Length(mm) |

1000(Size can customized) |

||||

| PCB Width |

50 to 350 mm |

||||

| UV Inspect Lighting |

N/A |

Standard |

Standard |

||

| Communication |

SMEMA |

||||

| Dimension(mm) |

1000*700*950 |

||||

| Weight |

75 Kg | 85 Kg | 95 Kg | ||

| PCBA Coating IR Oven |

|||||

| Model | IR3 | IR4 | IR8 | Customized |

|

| Transport |

Rail |

Rail |

Rail |

Rail |

|

| Control System |

Touch screen |

Instrument or PC |

Instrument or PC |

PC | |

| Heating Mode |

IR(Hot air Optional) |

|

|

||

| Number Of Heating Zones |

Up3 / Bottom0 |

Up4 / Bottom0 |

Up8 / Bottom0 |

Up9~24 / Bottom9~24 |

|

| Transport high |

900 ± 20mm |

900 ± 20mm |

900 ± 20mm |

900 ± 20mm |

|

| Maximum PCBA Height |

± 110mm |

± 110mm |

± 110mm |

Customized |

|

| Max.Width Of PCBA |

350mm |

350mm |

350mm |

Customized |

|

| Dimension (L*W*H)mm |

3000x950x1400 |

4000x950x1400 |

5000x950x1400 |

Customized |

|

| Weight | Approx.550KG |

Approx.850KG |

Approx.1150KG |

Customized |

|

| UV Curing Oven |

|||||

| Model | U1 | U2 | |

||

| Transport |

Teflon mesh belt |

Stainless steel chain |

Stainless steel chain |

||

| Control System |

Instrument |

PLC+touch screen |

PLC+touch screen |

||

| UV light quantity |

1 set | 2 set | 2 set | ||

| Transport high |

750+/-20mm |

900+/-20mm |

900+/-20mm |

||

| Maximum PCBA Height |

+80mm |

+100mm |

+100mm |

||

| Max.Width Of PCBA |

350mm | 450mm | 450mm | ||

| Dimension (L*W*H)mm |

1950x770x1700 |

1950x1000x1500 |

3000x1000x1500 |

||

| Weight | Approx.350KG |

Approx.420KG |

Approx.520KG | ||

Click Here Get More Informaion!

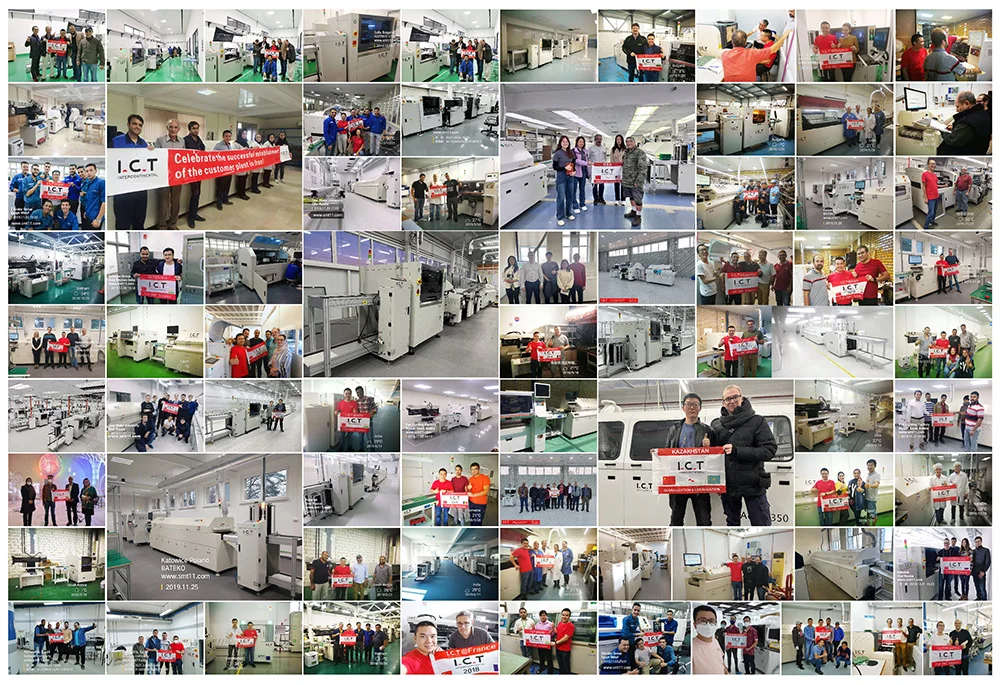

❙ I.C.T Customer Factory

❙ Company Profile

I.C.T is a manufacturer of SMT machines. It mainly provides customers with SMT Production Line including SMT Stencil Printer, Pick and place machine, Reflow Oven, SMT AOI Machine, Wave Soldering Machine and PCB Handling Machine etc.

I.C.T has more than 25 researches on SMT and DIP technology, for the world Customers provide SMT total solutions. There are successful cases of SMT technical team in Asia, Europe, America, Africa, and Australia.

I.C.T provide SMT solutions at various stages according to the different needs of customers. I.C.T is not only a provider of SMT equipment and technology, but also is the customer's escort in the field of SMT and DIP.

Successful Experience:

I.C.T's Customer In 35 Countries Around the World

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

Click Here Get More Informaion!

❙ I.C.T SMT Machine Exhibition

❙ I.C.T Global Service

Welcome more people to discuss with us about SMT technologies and solutions, please Contact Us for more information:

Tel: +86 13670124230 (WhatsApp/Skype/WeChat), Email: info@smt11.com / etasmt@foxmail.com

❙ PCBA Coating Conveyor Video