Panasonic NPM-D3 Modular SMT Placement

❙ Introduce of Panasonic SMT Placement

| Panasonic NPM-D3 electronics assembly chip shooter, Panasonic SMT placement, Panasonic PCB pick and place machine, with 16-nozzle head 84,000 CPH. |

1. Flexible board handling system converts to support single and multiple dual-lane operation modes

| Product name | Panasonic Chip Mounter NPM Series SMT Placement | ||||

| Model | NPM-D3 | NPM-W2 | NPM-TT2 | NPM-W2S | |

| Concept | Dual-gantry, multi-head, process-driven module |

Dual-gantry, multi-head, process-driven module |

Dual-gantry, multi-head, process-driven module |

Single-gantry, multi-head, process-driven module |

|

| Drive system | High-accuracy, low-maintenance, linear-motor driven gantry(s) system | ||||

| Component alignment | Multi-recognition digital camera | ||||

| Head design options | Inline array of 16, 12, 8, 3 and 2(D3) nozzle heads | ||||

| Applicable heads | 16, 12, 8, 2 | 16, 12, 8, 3 | 8, 3 | 16, 12, 8, 3 | |

| Board dimensions (Single lane) | L 510mm x W 590mm | L 750mm x W 550mm 1200mm long PCB opt |

L 510mm x W 590mm | L 750mm x W 550mm 1200mm long PCB opt |

|

| Board dimensions (Dual lane) | L 510mm x W 300mm L 510mm x W 550mm *1 |

L 750mm x W 260mm L 750mm x W 510mm *1 *2 |

L 510mm x W 300mm L 510mm x W 550mm *1 |

L 750mm x W 260mm L 750mm x W 260mm *1 *2 |

|

| Placement accuracy | Chip | ±25μ Cpk ≥ 1.0 *4 | ±25μ Cpk ≥ 1.0 *4 | ±40μ Cpk ≥ 1.0 | ±25μ Cpk ≥ 1.0 *4 |

| QFP | ±30μ Cpk ≥ 1.0 | ±30μ Cpk ≥ 1.0 | ±30μ Cpk ≥ 1.0 | ±30μ Cpk ≥ 1.0 | |

| Throughput | Ideal | Up to 84,000 CPH | Up to 77,000 CPH | Up to 36,000 CPH | Up to 38,500 CPH |

| IPC9850 | 63,300 CPH (1608C) *3 | 59,200 CPH (1608C) *3 | 8,300 CPH (208 QFP) *3 | 30,000 CPH (1608C) *3 | |

| Component range | Min | 03015 microchip *4 | 03015 microchip *4 | 0402 microchip | 03015 microchip *4 |

| Max | 100mm x 90mm | 150mm x 25mm | 150mm x 25mm | 150mm x 25mm | |

| Height | 28mm | 30mm | 30mm | 30mm | |

| Special height | - | 40mm | - | 40mm | |

| Insertion force | .5N ~ 50N | .5N ~ 100N | .5N ~ 100N | .5N ~ 100N | |

| Feeder capacity | Reels w/ no tray feeder | 68 | 120 | 120 | 120 |

| Reels w/ tray tower | 24 | 86 | 86 | 86 | |

| Reels w/ twin tower | N/A | 60 | N/A | 60 | |

| Reels w/ 2 tray towers | N/A | N/A | 52 | N/A | |

| Trays w/ tray tower | 20 | 20 | 20 | 20 | |

| Trays w/ twin or 2 tray towers | N/A | 40 | 40 | 40 | |

| Facilities | Electric | Voltage: 3 Phase AC 200/220 ±10V; AC 380 400 420 480V ±20V Frequency: 50/60 Hz | |||

| |

2.7KVA | 2.8KVA | 2.5KVA | 2.0KVA | |

| |

Peak current 30A @ 200V | Peak current 40A @ 200V | Peak current 38A @ 200V | Peak current 22A @ 200V | |

| |

Pneumatic | .5 ~ .8MPa, 100L/min | .5 ~ .8MPa, 200L/min | .5 ~ .8MPa, 200L/min | .5 ~ .8MPa, 200L/min |

| |

Mass | 1900kg w/ 2 carts | 2850kg w/ 2 carts | 3090kg w/ 2 carts | 2850kg w/ 2 carts |

Get More Information with Just One Click!

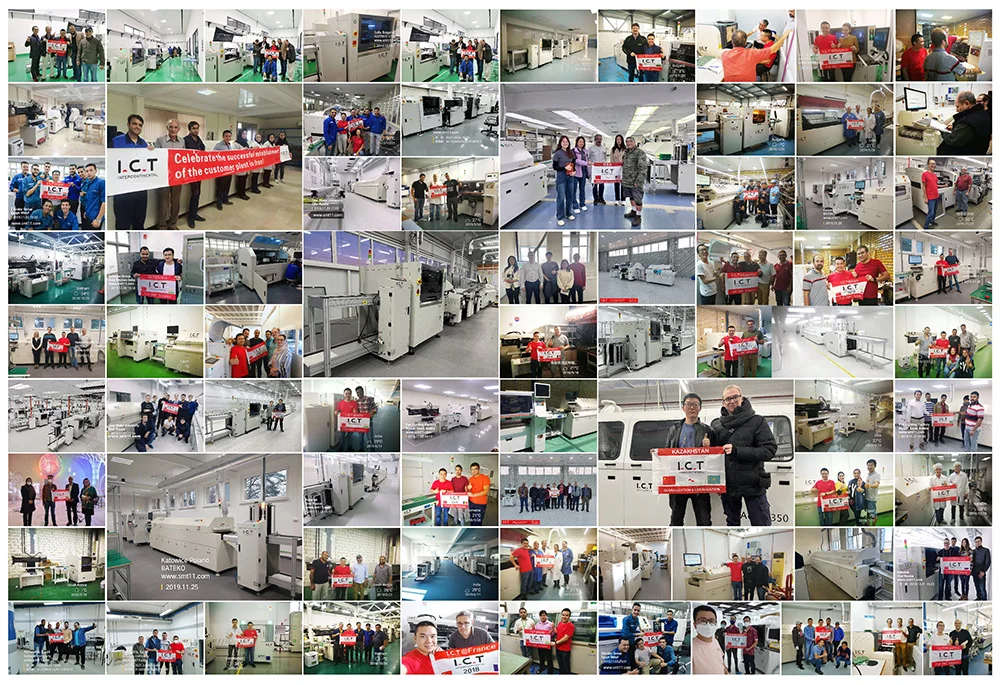

❙ Customers Factory ▽ I.C.T Russia customer - SMT production line

▽ I.C.T Ecuador customer - LED TV production line

Successful Experience:

I.C.T's Customer In 35 Countries Around the World

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT

❙ I.C.T SMT Machine Exhibition

❙ I.C.T Global Service

Get More Information with Just One Click!

❙ Keywords

SMT Pick and Place Machine, JUKI RS-1R Pick and Place Machine, JUKI RX-7R pick and place machine, Hanwha SM481 Plus Pick and Place Machine, SMT482Plus, SMT 471Plus, JUKI Pick and place Machine, Samsung Pick and Place Machine, Yamaha Pick and Place Machine, Panasonic SMT Placement, FUJI Chip Mounter, ASM SMD Placement.

I.C.T is a manufacturer of SMT Machines. It mainly provides customers with SMT Production Line including SMT Stencil Printer, Pick and place machines, Reflow Oven, SMT AOI Machine, Wave Soldering Machine and PCB Handling Machine etc.

I.C.T has more than 25 researches on SMT and DIP technology, for the world Customers provide SMT Solution. There are successful cases of SMT technical team in Asia, Europe, America, Africa, and Australia.

I.C.T provide SMT solutions at various stages according to the different needs of customers. I.C.T is not only a provider of SMT Equipment and technology, but also is the customer's escort in the field of SMT and DIP.

Tel: +86 13670124230 (WhatsApp/Skype/WeChat), Email: info@smt11.com / etasmt@foxmail.com

❙ Panasonic Pick and Place Machine Video