I.C.T. Double-Sided PCBA Coating Line: Enhances Surface Protection, Efficiency for Diverse Industries

Introduction of Double-Sided PCBA Coating Line

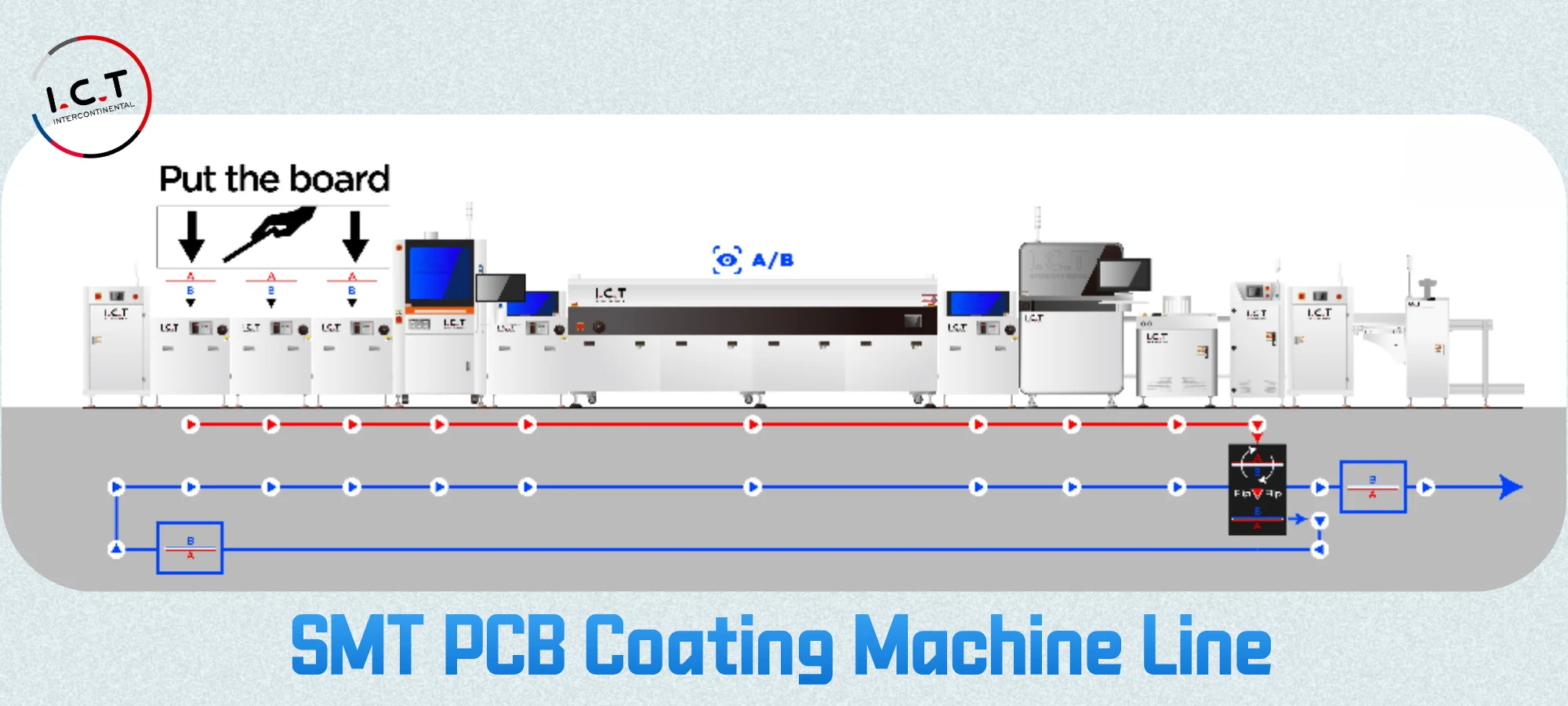

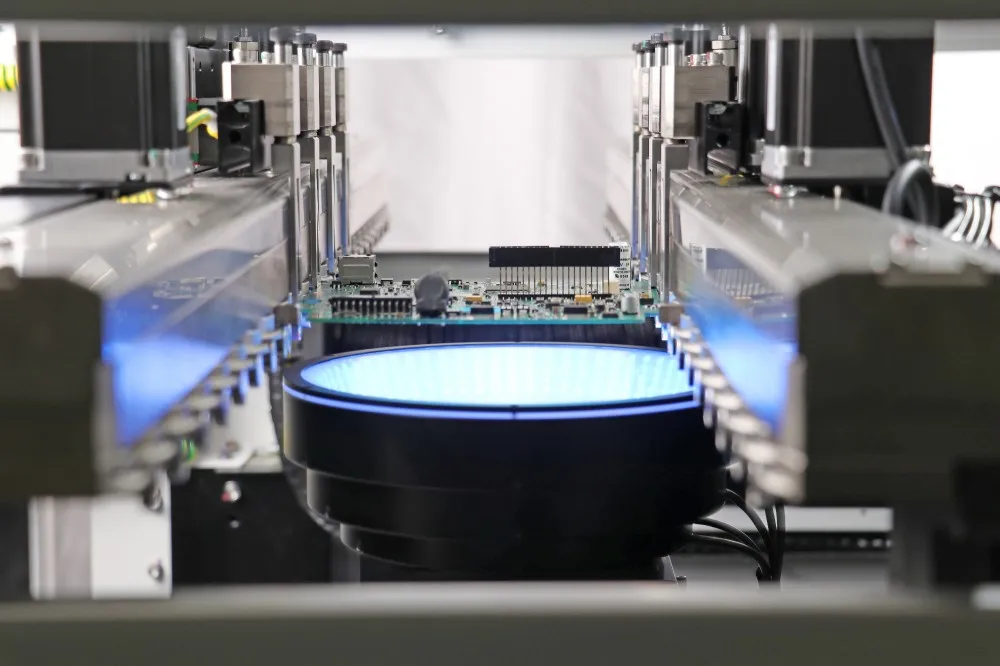

I.C.T introduces the PCB Double-Sided Coating Line, a cutting-edge solution catering to diverse manufacturing needs. This innovative technology enhances surface coating capabilities for PCBs, addressing the evolving demands of the industry.

Versatility for Varied Manufacturing Needs

I.C.T’s Answer to Diverse Requirements

The Double-Sided PCBA Coating Line from I.C.T caters to the growing demand for comprehensive surface coating on both sides of PCBs. It's a versatile solution suitable for a wide range of manufacturing applications.

Space-Efficient with Impressive Throughput

Efficiency in a Compact Space

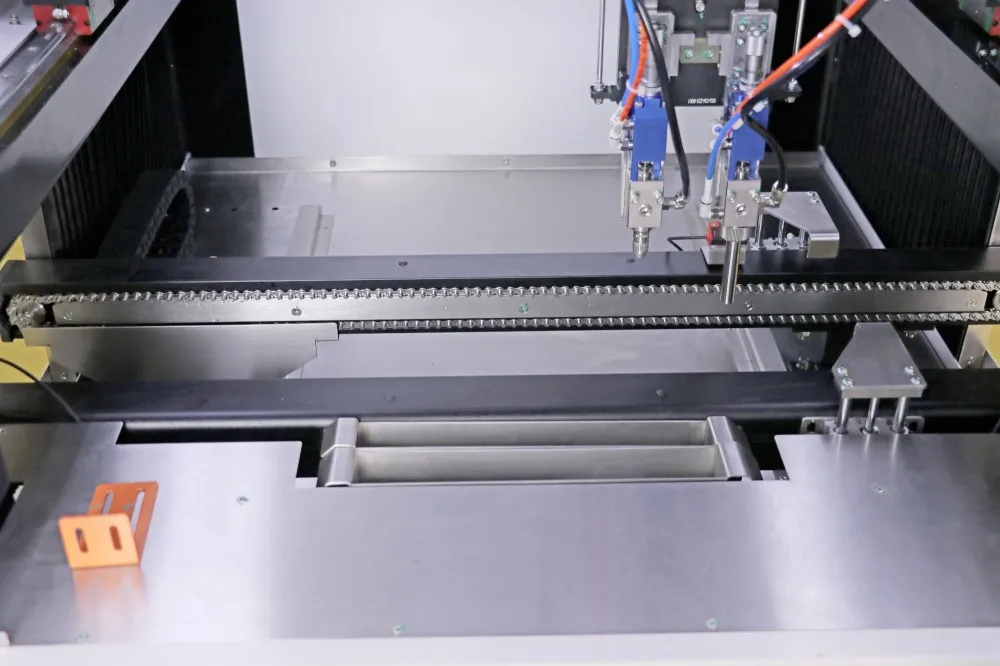

Occupying a modest 17*1.5 meters, the coating line boasts impressive throughput. Coating PCBs up to 710500mm, it achieves a notable production speed of 30 to 40 seconds per side, ensuring efficiency without compromising space. Learn more about the pcba conformal coating machine here.

Complete Equipment Setup for Seamless Manufacturing

All-Inclusive ConfigurationComprising a PCBA coating machine, SMT IR curing oven, coating AOI machine, lifting elevators, conveyors, inspection conveyors, and a PCB unloader, the Double-Sided PCBA Coating Line offers a complete and integrated manufacturing process.

Adaptable Curing Oven Technology

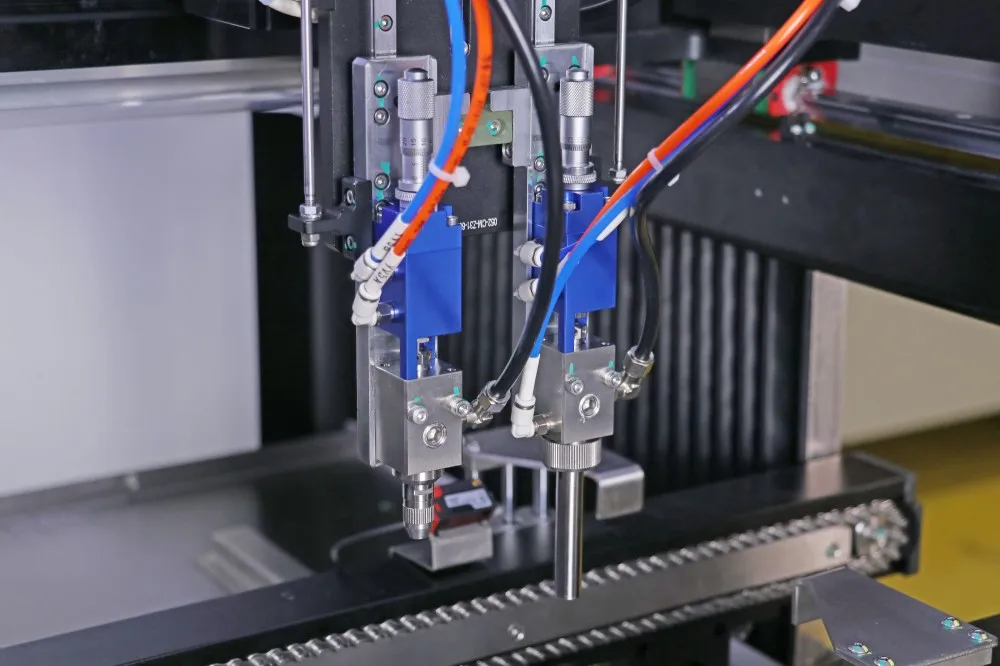

Flexibility in Adhesive CompatibilityThe curing furnace adapts to different adhesives – using PCB IR curing for standard adhesives and providing the option of a PCB UV curing oven for UV-curable adhesives, adding flexibility to the coating process.

Flexibility in Board Placement

Options for Board PlacementWith three conveyors, users can choose between manual board placement or the integration of a robotic arm for automated handling, providing flexibility to accommodate diverse production needs.

Features and Advantages of I.C.T's Innovative Coating Line

Customized Design with Return Track FunctionalityA standout feature is the return track functionality, efficiently looping back PCBs to the initial stage for further processing, enhancing the overall efficiency of the manufacturing process.

Innovations in Equipment Functionality

The scanning capability sets a new standard for innovation, allowing precise coating through QR code recognition. Coating AOI integration adds a layer of quality assurance by identifying and filtering out non-compliant PCBs.

Industry Applications and Impact

Broad Industry ApplicationsThe Double-Sided PCBA Coating Line caters to diverse industries, including automotive, industrial computing, aviation, military electronics, and consumer goods. It addresses specific environmental challenges in each sector.

Impact on Product Lifecycle and Quality

Coated boards significantly increase the lifespan of electronic devices, offering preventive measures against dust and water, resulting in enhanced product quality and durability.

Unmatched Service Commitment: I.C.T’s Comprehensive Offerings

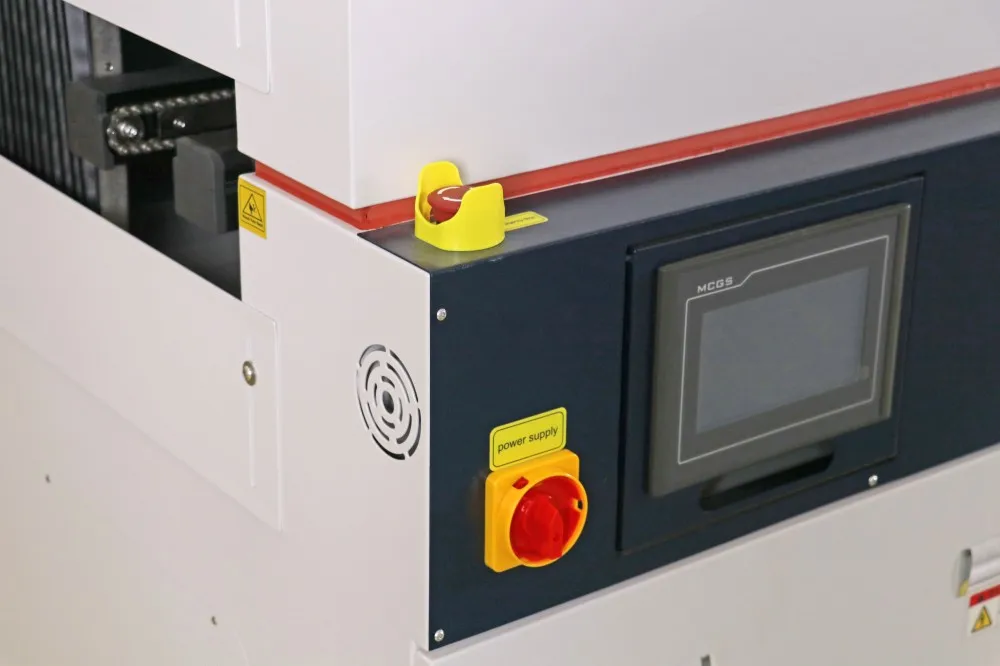

Safety Assurance with CE CertificationAll devices within I.C.T’s coating and SMT production lines carry a CE safety certificate, emphasizing a commitment to providing reliable and secure solutions for electronic manufacturing.

Global Service Experience

With a service footprint in 75 countries, I.C.T ensures equipment voltage configurations align with local power standards, ensuring seamless integration into operational setups.

Comprehensive Support for New Ventures

I.C.T offers comprehensive installation and training support, addressing the challenges faced by new manufacturers, ensuring a worry-free start for clients.