In the dynamic realm of Industry 4.0, I.C.T introduces the I.C.T-T550 SMT PCB coating machine, a pioneering addition designed to meet the evolving needs of modern manufacturing. This advanced equipment is equipped with features that not only boost productivity but also prioritize precise and consistent coating quality. Let’s delve into the crucial attributes that establish the I.C.T-T550 as a vital component in your production process.

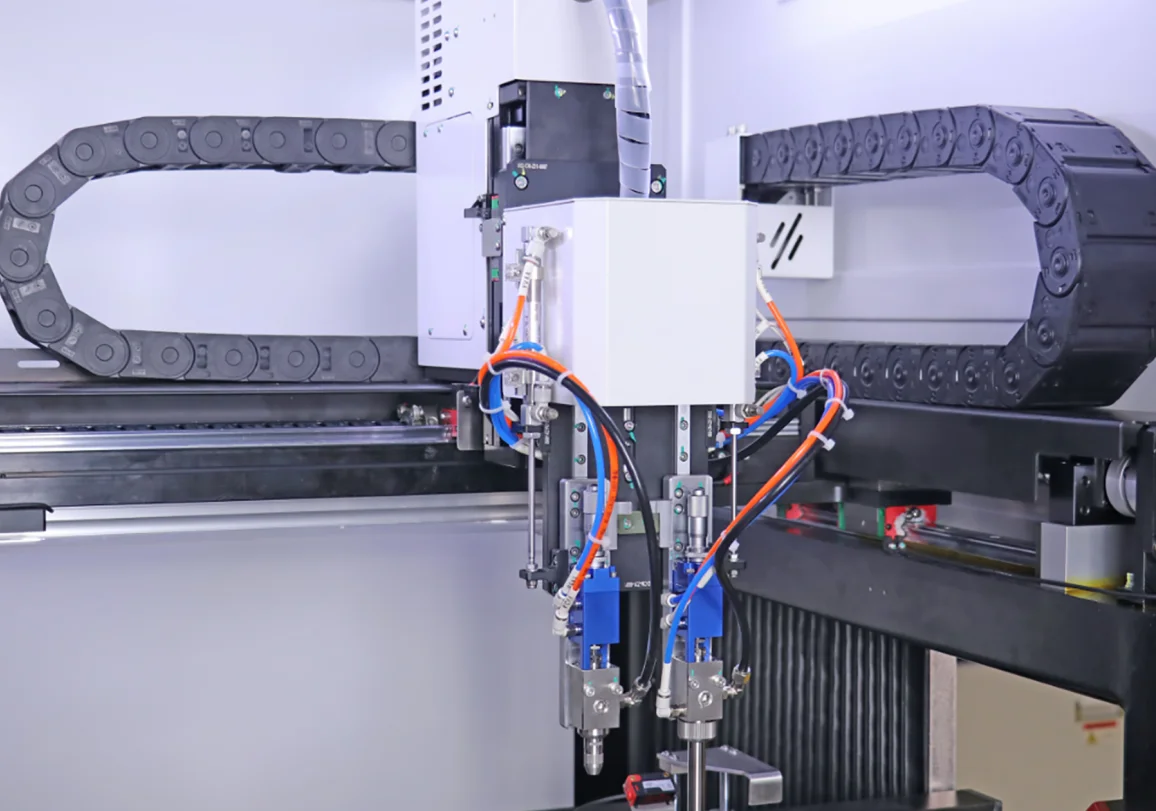

1. Automated Precision for Coating Consistency

The I.C.T-T550 PCB Coating Machine integrates an automated pressure regulation system for both dispensing valve and pressure tank, equipped with precision regulators and digital gauges. This ensures a consistent coating process, optimizing precision.

2. Front-End Accessibility for Operational Efficiency

Located at the front end, power supply and air pressure adjustments are easily accessible, streamlining control. This user-friendly design enhances operator workflow efficiency.

3. Durable Material Transport

The open-material transport rail undergoes hardening treatment and utilizes a specialized stainless steel chain drive, ensuring both longevity and reliable material transport.

4. Track Width Adjustment for Trouble-Free Operation

Track width adjustment is achieved through a synchronous belt drive mechanism, ensuring prolonged and trouble-free operation.

5. CNC Machined Frame for Unparalleled Precision

The machine’s frame, subjected to CNC machining, features an independent, all-steel gantry frame, ensuring the parallel alignment of tracks and axes.

6. Workshop Environment Enhancement

To ensure a cleaner and safer workspace, the equipment features air curtains at the track entrance and exit, preventing fumes from escaping. It also includes a dedicated exhaust outlet, improving overall workshop air quality.

7. Intuitive Programming and Visualization

The I.C.T-T550 PCB Coating Machine allows flexible coating path editing through intuitive programming. The equipment employs a teach mode for programming, offering a visual interface for coating path design.

8. User-Friendly Interface with Practical Design

Featuring a user-friendly interface with fault alerts and menu displays, the I.C.T-T550 delivers a sleek and practical design.

9. Streamlined Repetition and Data Management

Efficiency is paramount, and the I.C.T-T550 offers the ability to mirror, array, and replicate coating paths, simplifying the process, especially with multiple boards.

10. Real-Time Data Monitoring

The equipment automatically collects and displays data, including production volume and individual product work times, enabling effective production performance tracking.

11. Smart Adhesive Management

The I.C.T-T550 intelligently monitors adhesive levels, providing automatic alerts for replenishment, ensuring uninterrupted coating.

In summary, the I.C.T SMT PCB coating machine seamlessly combines precision, automation, and smart features to meet the demands of Industry 4.0. With integration into MES systems, it provides a reliable and efficient solution for elevating PCB coating processes.

The I.C.T-T550’s adherence to European safety standards and CE certification underscores our commitment to safety and compliance. For further inquiries or information about additional safety standards, please contact us.

Whether optimizing coating quality or enhancing factory productivity, the I.C.T-T550 marks a step into the future of intelligent manufacturing. Explore a variety of coating valves or seek guidance by reaching out to us.