Elevate your electronic manufacturing game with the I.C.T-D600 SMT Dispensing Machine! Precision, safety, and efficiency in one powerful solution.

In the dynamic realm of electronic manufacturing, precision and efficiency are not just preferences but essential requirements. Introducing the I.C.T-D600, an automatic glue dispenser machine engineered to enhance production processes across various applications. From chip encapsulation to PCB assembly, SMT red-glue dispensing, LED lens production, and medical device creation, SMT dispensing machine is a versatile solution tailored to meet the demands of the industry.

Essential Attributes Of The I.C.T-D600 Automatic Glue Dispenser Machine

1. Compliance with European Safety Standards:

The I.C.T-D600 SMT dispensing machine prioritizes not only efficiency but also safety, boasting compliance with European safety standards and holding a CE certificate. This ensures a secure and reliable manufacturing environment, aligning with global quality benchmarks.

2. International Component Quality:

Internationally renowned components form the core of the D600 SMT dispensing machine. From Panasonic servomotors to MINTRON CCD, each element is carefully selected, guaranteeing high performance and durability. This commitment to quality components results in a machine that operates seamlessly, reducing downtime and maintenance costs.

3. Impressive Performance Metrics:

The SMT dispensing machinedoesn’t just meet expectations; it surpasses them with exceptional performance metrics:

- Maximum Guide Rail Speed: 400mm/s

- Fastest Injection Valve Speed: 20 spots/sec

- Dispensing Accuracy: ±0.02mm

- Repeated Accuracy: ±0.01mm

Machine Characteristics:

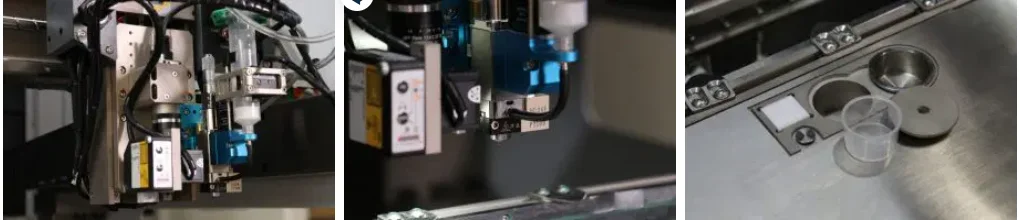

Core Part – Jet Valve

The non-contact jet dispensing method ensures high-speed operation (max jet speed: 20 spots/second), high accuracy with a minimum dispensing volume of 5nl, and flexibility with extremely small dispensing volumes. The thermostatic system for the flow channel and sprayer ensures uniform glue temperature, resulting in low maintenance costs and an extended service life.

Enhanced Capacity:

- Non-contact jet dispensing eliminates the need for Z-axis motion.

- Integrated temperature control technology reduces manual intervention.

- Automatic glue compensation minimizes artificial regulation time.

- Dual-track design reduces waiting time.

- Automatic visual location identification and compensation.

- Non-contact height detection with laser reduces height detection time.

Flexibility:

- Capable of handling substrates or backings of various sizes.

- Optional heating module.

- Independent control of dual tracks with user-friendly software.

- Fast switching between different product lines.

- Universal platform suitable for various processes with different glues

-