Introduction: Navigating Precision Manufacturing Challenges

Precision manufacturing, especially in Surface Mount Technology (SMT) production, demands meticulous attention to detail. Among the myriad challenges faced, Electrostatic Discharge (ESD) emerges as a formidable threat to electronic components. In this article, we embark on a journey through the intricacies of ESD systems, underscoring their pivotal role in fortifying production lines against potential disruptions.

Unveiling Electrostatic Discharge Systems: A Primer

Defining Electrostatic Discharge Systems

Electrostatic Discharge Systems are designed to counteract the sudden flow of electric current between objects with differing electric potentials. This rapid transfer of electrostatic charge, often manifesting as sparks or rapid current flow, poses a significant risk to the delicate electronic components prevalent in precision manufacturing.

Understanding the Impact of Electrostatic Discharge Systems on Electronic Components

The repercussions of Electrostatic Discharge Systems on electronic components are profound, potentially leading to irreversible damage, latent defects, or a shortened component lifespan. A nuanced understanding of the causes and effects of ESD is paramount for shielding sensitive components and ensuring consistent, high-quality production.

Strategic Approaches to Manage Electrostatic Discharge Systems

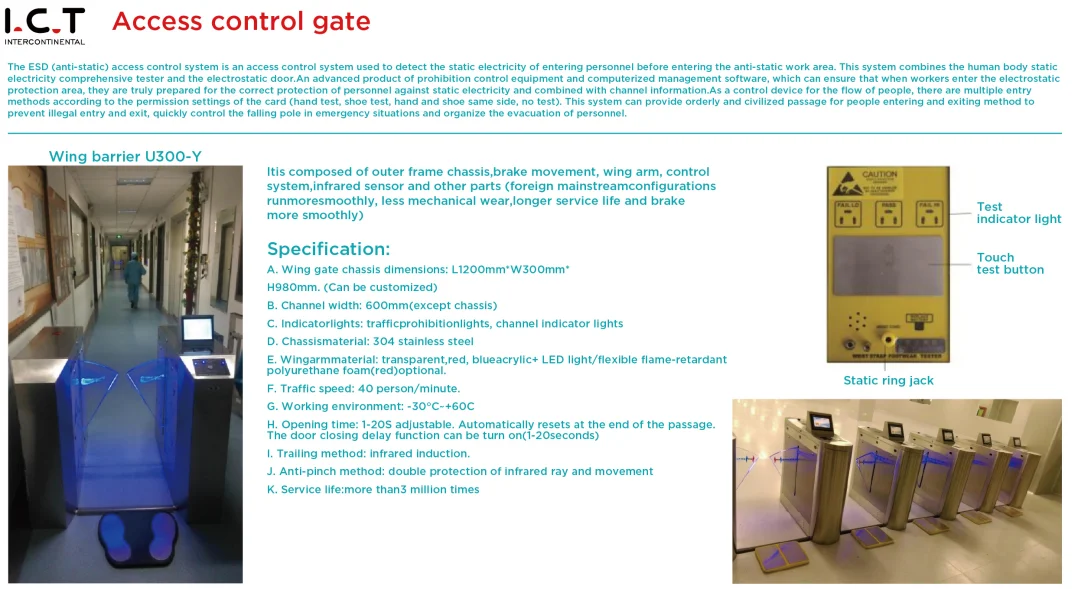

Effectively managing and preventing Electrostatic Discharge (ESD) risks necessitates strategic approaches. This includes establishing ESD-Protected Areas (EPAs), deploying Personal Protective Equipment (PPE), implementing proper grounding measures, and utilizing ESD-safe packaging materials.

Adherence to Electrostatic Discharge Systems Standards: A Cornerstone of Protection

Strict adherence to recognized ESD standards, such as ANSI/ESD S20.20, IEC 61340 series, and MIL-STD-883E, is imperative for maintaining a robust defense against electrostatic discharge. These standards form the backbone of a comprehensive Electrostatic Discharge System.

The Vital Role of Electrostatic Discharge Systems in Precision Manufacturing

The Need for Electrostatic Discharge Systems

In the realm of precision manufacturing, Electrostatic Discharge Systems are indispensable. These intricate networks of devices and processes effectively control and minimize the buildup of static electricity, safeguarding components and ensuring the consistency and reliability of production processes, especially in SMT.

Constructing Factory Electrostatic Discharge Systems: A Three-Fold Strategy

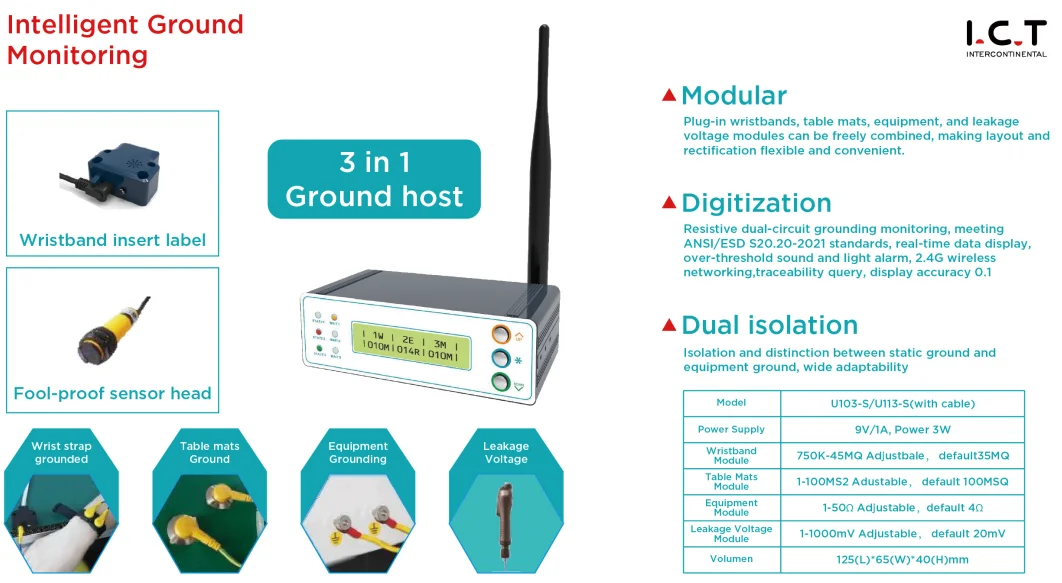

Building an Electrostatic Discharge System for an SMT factory demands a three-pronged approach: protection, elimination, and monitoring. This involves the installation of anti-static mats, grounding straps, ionizers, and air purifiers to create barriers, eliminate static electricity, and monitor static levels in real-time.

Tailoring Electrostatic Discharge Systems for SMT and DIP Production Lines

Tailored ESD systems are imperative for SMT and DIP production lines. Identification of critical areas, implementation of suitable ESD systems, and ensuring robust grounding measures are in place are pivotal. Real-time monitoring through ESD sensors and meters facilitates swift problem identification and compliance with ESD standards.

Applications of Electrostatic Discharge Systems: Exploring Advanced Solutions

Intelligent Ground Monitoring Systems: Enhancing Foundation Strength

Intelligent DC Ion Blower: Unseen Protection Unleashed

Air Shower/Cargo Shower Systems: Purity in Every Particle

Access Control Gates: Precision Through Restriction

Contact Us now for a free ESD solution consultation and secure the future of your precision manufacturing.