Squeegee Cleaning Machine I.C.T-4200

❙ Introduce of PCBA Cleaning Machine

I.C.T-4200 Fixture Cleaning Machine is used to clean grease, solder paste, dusts on the surface of all kinds of SMT Printer Squeegee,tray, reflow oven cooler and filter , chains, and nets...etc.

I.C.T-4200 is made up of wash unit, rinse unit, dry unit, rotation cleaning basket unit and control unit. Put the dirt SMT squeegee on to the cleaning basket, setting the cleaning parameters, the machine will automatically complete wash, rinse and dry process by just pushing start key. The squeegee after cleaning is very clean and dry, ready to use at any time.

Features

1.Total SUS 304 structure, resist Acid and Alkali corrosion, firm and attractive.

2.1 meter diameter big cleaning round basket, can clean 20~40 pcs fixtures at one time.

3.Clean liquid spray from 3 spray rods on upper/lower and front side, cleaning basket rotates during cleaning.

4.Clean liquid pressure up to 6kg/cm2, make it throughly clean of whole fixture.

5.PLC program control, Touch-panel operation,cleaning parameters can be set and change conveniently.

6.Easy One-button operation, high pressure clean+ rinse+ hot air dry, all process complete in a cycle automatically.

7.Clean liquid and water heat and temperature keeping function.

8.Closed-loop clean and rinse, clean detergent and rinse water are cycling filtered and reused in the machine. 9.Standard equipped solution and water auto fill in and discharge function.

10.The squeegee are clean and dry after cleaning, standby and ready for use at any time.

❙ Specification of PCBA Cleaning Machine

| Item | I.C.T-4200 |

| Cleaning basket size |

Φ1000mm x H 200mm. Special size option |

| Spray unit |

Upper/lower/front side,720°all-around spray |

| 3-level filter system |

1mm /50um/20um filters |

| Dilution capacity |

80L |

| Rinse tank capacity |

80L |

| Clean spray pressure |

5~6 kg/cm2 |

| Clean time |

5~15min |

| Rinse time | 1~3min |

| Dry time |

10~30min |

| Rinse detergent heat temp |

Room temp~80°C |

| Rinse water heat temp |

Room temp~80°C |

| Hot air heat temp |

Room temp~90°C |

| Clean pump power |

2.2KW |

| Clean detergent power |

9KW |

| Hot air heat power |

9KW |

| Air blower power | 4.0KW |

| Air supply |

0.5~0.7Mpa |

| Power supply |

3 P,AC 380V,50/60HZ,33KW |

| Machine size |

L1380 x W2100 x H 1400 (mm) |

| Machine weight |

500KG |

Click Here Get More Informaion!

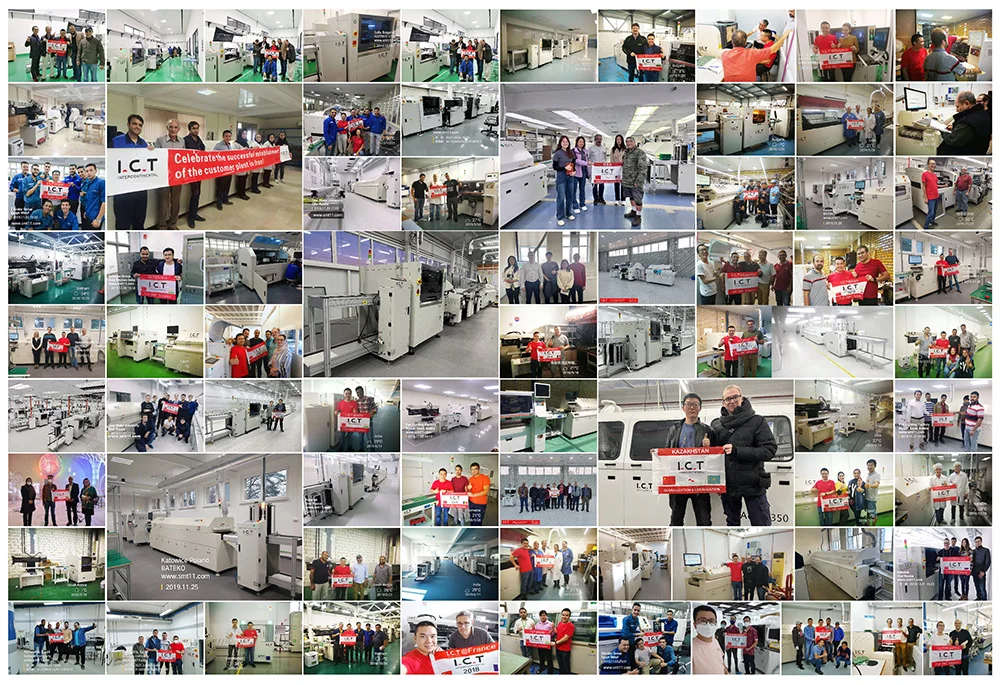

❙ I.C.T Customer Factory

❙ Company Profile

I.C.T is a manufacturer of SMT machines. It mainly provides customers with SMT Production Line including SMT Stencil Printer, Pick and place machine, Reflow Oven, SMT AOI Machine, Wave Soldering Machine and PCB Handling Machine etc.

I.C.T has more than 25 researches on SMT and DIP technology, for the world Customers provide SMT total solutions. There are successful cases of SMT technical team in Asia, Europe, America, Africa, and Australia.

I.C.T provide SMT solutions at various stages according to the different needs of customers. I.C.T is not only a provider of SMT equipment and technology, but also is the customer's escort in the field of SMT and DIP.

Successful Experience:

I.C.T's Customer In 35 Countries Around the World

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

Click Here Get More Informaion!

❙ I.C.T SMT Machine Exhibition

❙ I.C.T Global Service

❙ FAQ

A: Leading SMT Supplier in China; Trade assurance to USD 560,000+; Professional after-sales service team.

Welcome more people to discuss with us about SMT technologies and solutions, please Contact Us for more information:

Tel: +86 13670124230 (WhatsApp/Skype/WeChat), Email: info@smt11.com / etasmt@foxmail.com

❙ I.C.T PCBA Cleaning Machine