❙ Introduce of Automatic Intelligence Splicing Machine

I.C.T SMT Automatic Splicing Machine is developed to meet the requirements of SMT automatic production line for fast refueling without shutdown. It can automatically detect the position of empty component, accurately cut and over probability of more than 98% for the head and tail of two rolls of material belts with the same specification. It can be equipped with RC measurement function to reduce dependence on manpower, reduce management cost, improve detection efficiency, improve the production rate of SMT production line and avoid batch misfeeding, I.C.T SMT splicing machine has completed the full coverage of 4-72mm feeder.

❙ Specification of Automatic Soldering Robot

| Model | I.C.T-SR300 |

I.C.T-SR530 |

I.C.T-SR250D |

I.C.T-SR250DD |

| Platform Number |

1 | 1 | 2 | 2 |

| Head Number |

1 | 2 | 1 | 2 |

| Heating Power |

150W | 300W | 150W | 300W |

| Max. PCB Size(mm) |

300*300 |

500*300 |

250*250 for each Platform |

250*250 for each Platform |

| Driving Mode |

Step Motor |

|||

| Control Mode |

Teach Pendant |

|||

| Dimension(mm) |

620*660*770 |

780*660*770 |

780*660*770 |

780*660*770 |

| Weights | 60 Kg | 65 Kg |

70 Kg |

75 Kg |

Click Here Get More Informaion!

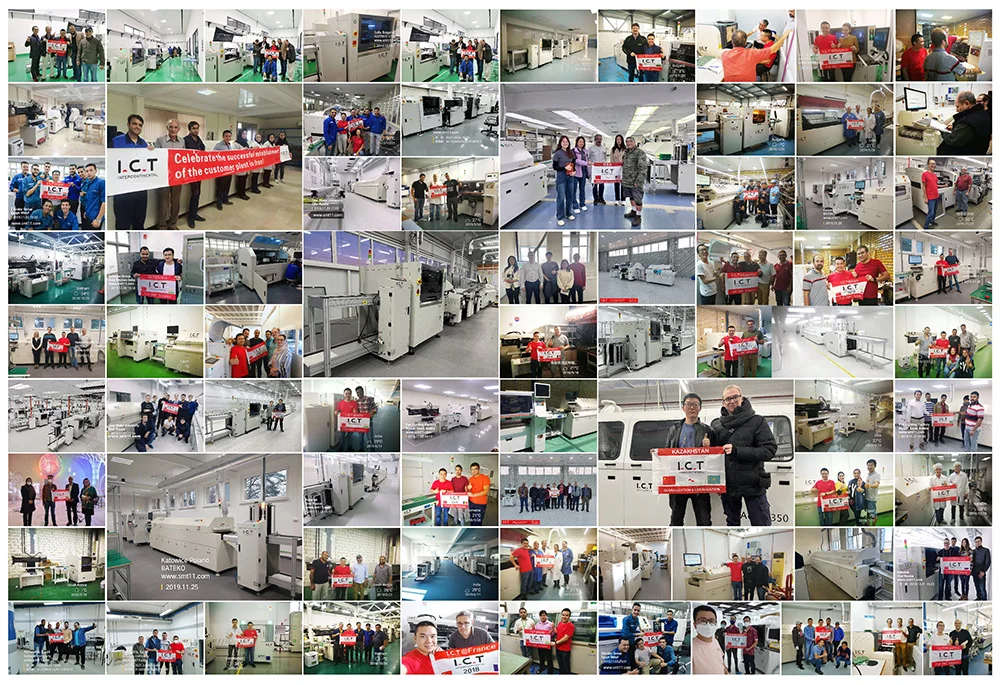

❙ I.C.T Customer Factory

❙ Company Profile

I.C.T is a manufacturer of SMT machines. It mainly provides customers with SMT Production Line including SMT Stencil Printer, Pick and place machine, Reflow Oven, SMT AOI Machine, Wave Soldering Machine and PCB Handling Machine etc.

I.C.T has more than 25 researches on SMT and DIP technology, for the world Customers provide SMT total solutions. There are successful cases of SMT technical team in Asia, Europe, America, Africa, and Australia.

I.C.T provide SMT solutions at various stages according to the different needs of customers. I.C.T is not only a provider of SMT equipment and technology, but also is the customer's escort in the field of SMT and DIP.

Successful Experience:

I.C.T's Customer In 35 Countries Around the World

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

Click Here Get More Informaion!

❙ I.C.T SMT Machine Exhibition

❙ I.C.T Global Service

Welcome more people to discuss with us about SMT technologies and solutions, please Contact Us for more information:

Tel: +86 13670124230 (WhatsApp/Skype/WeChat), Email: info@smt11.com / etasmt@foxmail.com