❙ Introduce of Coating Online AOI

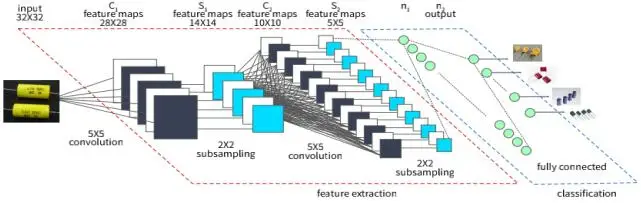

I.C.T Coating Online AOI AI-5146C for conformal coating inspection,captures board image in real time by high precision color industrial camera. Adopt Convolutional Neural Network (CNN) algorithm to process images. Judge defects of components intelligently. Features: 1. Online AOI for conformal coating inspection. 2.Intelligently lock coating border,Automatically identify coating area. 3.Able to coating defects. DIP defects, SMT defects, soldering defects and other defects can be application after switching light source. 4.Support multi-in-1 panel and mixed model inspection. 5.Simplified programming flow, very simple interface. Support batch modifying parameters with one-key. 6.Centralized control. Interconnection between multiple equipment. 7.Real-time inspection without stopping the board. 8.Apply UV light source, the glue containing phosphorus can clearly distinguish. 9.Multiple configurations (whole board, double side) are available. 10.Intelligently judge bubble of targeted area,Minimum bubble diameter is up to 0.05mm. 11.Data is traceable. Support SPC alarm,LOG automatic collecting and storage,NG warning/alarm function, Remote programming&debugging. 12.UV glue thickness measurement function optional.

❙ Specification of DIP On-line Dual Side Online AOI

| Model |

I.C.T Coating Online AOI AI-5146C |

I.C.T Coating Online AOI AI-5146CW |

| FOV |

15um@36*30mm(standard), 10um@24*20mm 15um@45x45mm,10um@40*30mm |

21.5um@52.6*44mm(standard), 15um@36*30mm/12MP:10um@40*30mm 15um@60*45mm |

| Resolution |

15um(standard) /10um

|

21.5um(standard) /15um /10um

|

| Camera Light |

Single side camera12M Dual side camera 5M Light UV + W light, (UV + RGBW) Inspection Speed 0.23sec/FOV |

|

| Power |

AC220 50/60Hz,5A |

|

| Communication |

SMEMA |

|

| Weight |

750Kg |

890Kg |

| Dimension |

L900*W1080*H1540mm |

L1050*W1335*H1650mm |

❙ Company Profile

I.C.T is a manufacturer of SMT machines. It mainly provides customers with SMT Production Line including SMT Stencil Printer, Pick and place machine, Reflow Oven, SMT AOI Machine, Wave Soldering Machine and PCB Handling Machine etc.

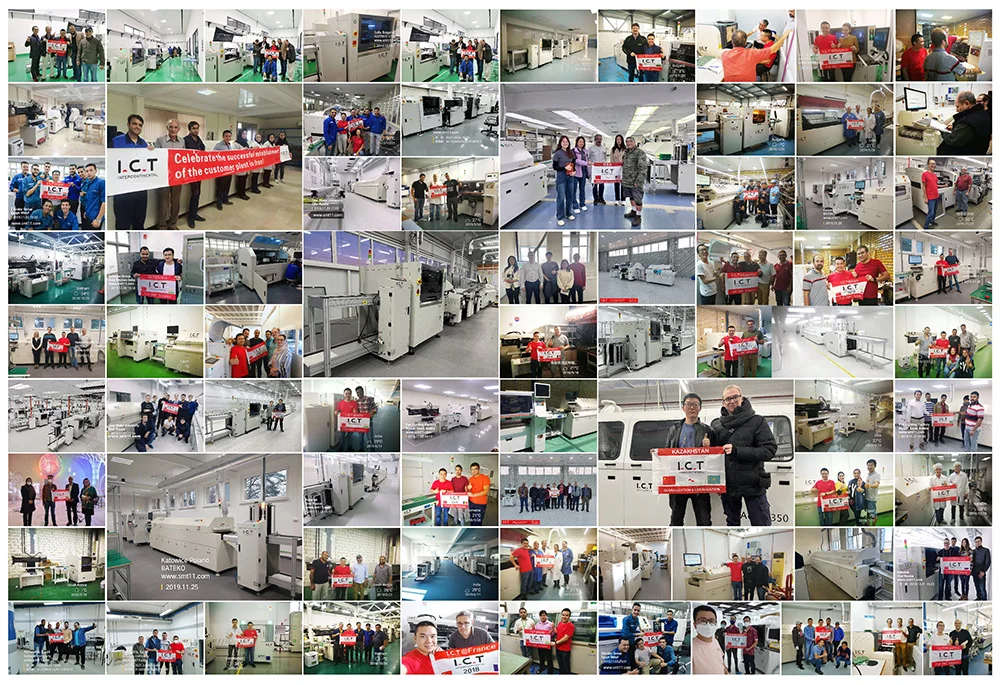

I.C.T has more than 25 researches on SMT and DIP technology, for the world Customers provide SMT total solutions. There are successful cases of SMT technical team in Asia, Europe, America, Africa, and Australia.

I.C.T provide SMT solutions at various stages according to the different needs of customers. I.C.T is not only a provider of SMT equipment and technology, but also is the customer's escort in the field of SMT and DIP.

Successful Experience:

I.C.T's Customer In 35 Countries Around the World

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

Click Here Get More Informaion!

❙ I.C.T SMT Machine Exhibition

❙ I.C.T Global Service

Welcome more people to discuss with us about SMT technologies and solutions, please Contact Us for more information:

Tel: +86 13670124230 (WhatsApp/Skype/WeChat), Email: info@smt11.com / etasmt@foxmail.com

❙ I.C.T Coating Online AOI Video