❙ Features of Yamaha Chip Mounter

SMT SMD assembly line machine Yamaha high speed pick and place machine, Yamaha placement, Yamaha chip mounter, have dual lane assembly delivers a seamless and efficient electronics assembly production process.

❙ Specification of Yamaha Chip Mounter

| Model |

YSM20R TypePV | YSM20R TypeSV | YSM20WR |

| Applicable PCB | Single lane L810 x W490 to L50 x W50 Dual stage Note: For X-axis 2-beam option only1PCB conveyance: L810 x W490 to L50 x W50 2PCB conveyance: L380 x W490 to L50 x W50 |

Dual lane Note 1 Same type PCBs: L810 x W356 to L50 x W50 Different type PCBs: up to L810 x W662 Note 2 Same type PCB: L810 x W280 to L50 x W500 Different type PCBs: up to L810 x W510 |

|

| Head / Applicable components | High-Speed Multi (HM) Head Note 3: 0201 to W55 x L100mm, Height 15mm or less Odd-shaped components (FM: Flexible Multi) head: 03015 to W55 x L100mm, Height 28mm or less |

High-Speed Multi (HM) Head: 03015 to W55 x L100mm, Height 15mm or less Odd-shaped components (FM: Flexible Multi) head: 03015 to W55 x L100mm, Height 28mm or less |

High-Speed Multi (HM) Head Note 3: 0201 to W55 x L100mm, Height 15mm or less Odd-shaped components (FM: Flexible Multi) head: 03015 to W55 x L100mm, Height 28mm or less |

| Mounting capability (under optimum conditions as defined by Yamaha Motor) |

X axis 2-beam: High-speed multi-purpose (HM: High-speed Multi) head x 2 95,000CPH |

X axis 2-beam: High-speed multi-purpose (HM: High-speed Multi) head x 2 90,000CPH |

X axis 2-beam Note 1: High-speed multi-purpose (HM: High-speed Multi) head x 2 |

| Mounting accuracy | ±0.035mm (±0.025mm) Cpk≧1.0 (3σ) (under optimum conditions as defined by Yamaha Motor when standard evaluation materials are used) | ||

| Number of component Types | Fixed plate: Max. 140 types (conversion for 8mm tape feeder) Feeder carriage exchange: Max. 128 types (conversion for 8mm tape feeder) Trays for 30 types (Fixed type: max., when fitted with sATS30) and 10 types (Carriage type: max., when fitted with cATS10) |

||

| Power supply | 3-Phase AC 200/208/220/240/380/400/416V +/-10% 50/60Hz | ||

| Air supply source | 0.45MPa or more, in clean, dry state | ||

| External dimension (excluding projections) | L 1,374 x W 1,857 x H1,445mm (Main unit only) | L 1,374 x W 2,110 x H1,445mm (Main unit only) | |

| Weight | Approx. 2,050kg (Main unit only) |

Approx. 2,500kg (Main unit only) | |

Get More Information with Just One Click!

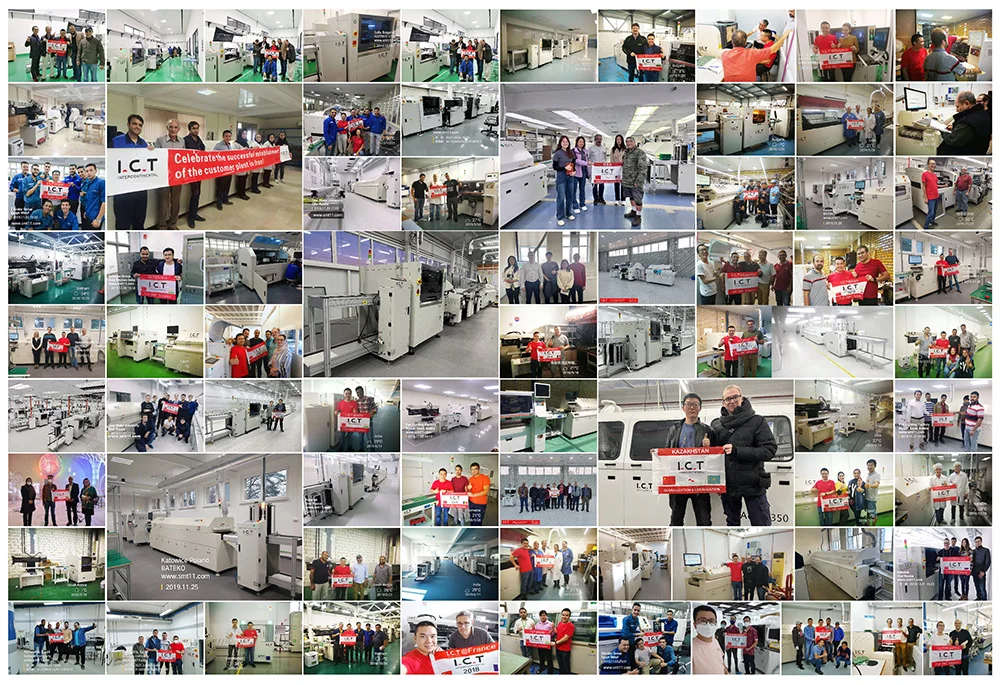

❙ Customers Factory ▽ I.C.T Russia customer - SMT production line

▽ I.C.T Ecuador customer - LED TV production line

Successful Experience:

I.C.T's Customer In 35 Countries Around the World

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

❙ I.C.T SMT Machine Exhibition

❙ I.C.T Global Service

Get More Information with Just One Click!

❙ Keywords

SMT Pick and Place Machine, JUKI RS-1R Pick and Place Machine, JUKI RX-7R pick and place machine, Hanwha SM481 Plus Pick and Place Machine, SMT482Plus, SMT 471Plus, JUKI Pick and place Machine, Samsung Pick and Place Machine, Yamaha Pick and Place Machine, Panasonic SMT Placement, FUJI Chip Mounter, ASM SMD Placement.

I.C.T is a manufacturer of SMT Machines. It mainly provides customers with SMT Production Line including SMT Stencil Printer, Pick and place machines, Reflow Oven, SMT AOI Machine, Wave Soldering Machine and PCB Handling Machine etc.

I.C.T has more than 25 researches on SMT and DIP technology, for the world Customers provide SMT Solution. There are successful cases of SMT technical team in Asia, Europe, America, Africa, and Australia.

I.C.T provide SMT solutions at various stages according to the different needs of customers. I.C.T is not only a provider of SMT Equipment and technology, but also is the customer's escort in the field of SMT and DIP.

Tel: +86 13670124230 (WhatsApp/Skype/WeChat), Email: info@smt11.com / etasmt@foxmail.com

❙ Yamaha Chip Mounter Video