❙ Introduce of PCBA Cleaning Machine

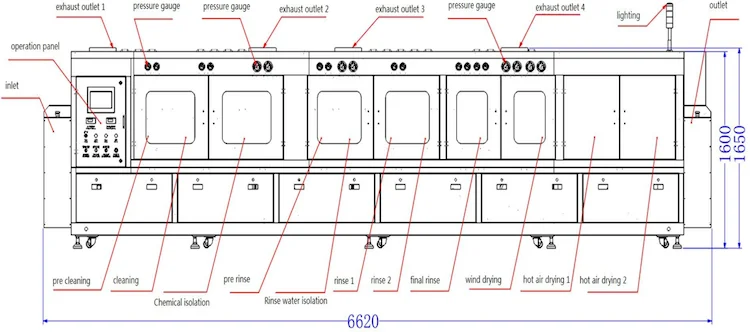

I.C.T-6300 is PCBA online cleaning machine, mainly used for batch PCBA, automatic cleaning, including chemical cleaning, DI water rinsing and hot air drying.

The unique high-pressure spray cleaning process with large flow and high-pressure spray and belt conveyor system can automatically complete the chemical cleaning, DI water rinsing and hot air drying in one machine.

In PCBA→pre cleaning→cleaning→chemical isolation→pre rinsing→rinsing isolation→rinsing 1→rinsing 2→final spray rinsing→air drying→hot air drying 1→hot air drying 2→out PCBA.

Features

1.Through clean rosin flux, water-soluble flux, non-clean flux, solder paste and other organic and inorganic contaminations.

2.2-layers cleaning basket: 610mm(L) ×560mm(W) × 100mm(H) x2 layers.

3.State of the process is visible through a large observation window.

4.Clean detergent heat system heat cleaning detergent to a certain temp, raise cleaning efficiency and reduce clean time.

5.Easy operation interface, quick setting clean parameters. Different passwords can be set.

6.Inner filter makes detergent used repeated. Real-time measure DI water resistivity and monitoring cleaning effect. Resistivity range is 0~18 MΩ.

7.The remaining detergent in the pump and pipes are blown off by compressed air and flow back to cleaning tank. This function saves detergent up to 50%.

8.High standard cleanliness, ionic contamination completely meets the requirement of IIPC-610D I class.

9.Totally SUS304 structure, very firm and attractive.

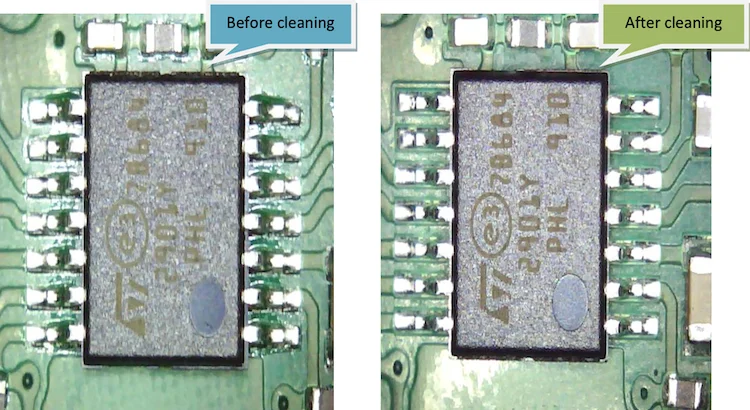

Effect comparison:

❙ Specification of PCBA Cleaning Machine

| Item | I.C.T-5600 |

| Mesh width |

500 mm |

| PCBA max.size |

400~500mm(L*W) |

| PCBA min.size |

30~30mm(L*W) |

| Machine size |

5200(L)x1650(W)X1650(H) mm |

| Machine weight |

2800KG |

❙ I.C.T Customer Factory

▽ Russia SMT production line (smart appliances)

▽ Algeria LED TV production line

❙ Company Profile

I.C.T is the SMT machine supplier with professional 25-year-experienced sales and after sales team, providing SMT solutions including pick and place machine, reflow oven, SMT stencil printer, SMT line and wave soldering machine.

Successful Experience:

I.C.T's Customer In 35 Countries Around the World

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT

❙ I.C.T SMT Machine Exhibition

❙ PCB Cleaning Machine Certificate

❙ I.C.T Global Service

❙ FAQ

If you could not find any similar items you want, you may send some photos to us. because our catalog and website haven't included all of our products.

I.C.T is a manufacturer of SMT machines. It mainly provides customers with SMT production lines including SMT Stencil Printers, Pick and place machines, Reflow Oven, AOI Machine, Wave Soldering Machine and PCB Handling Machine etc.

I.C.T has more than 25 researches on SMT and DIP technology, for the world Customers provide SMT total solutions. There are successful cases of SMT technical team in Asia, Europe, America, Africa, and Australia.

I.C.T provide SMT solutions at various stages according to the different needs of customers. I.C.T is not only a provider of SMT equipment and technology, but also is the customer's escort in the field of SMT and DIP.

Welcome more people to discuss with us about SMT technologies and solutions, please contact us for more information:

Tel: +86 13670124230 (WhatsApp/Skype/WeChat)

Email: info@smt11.com /etasmt@foxmail.com

❙ I.C.T PCBA Cleaning Machine