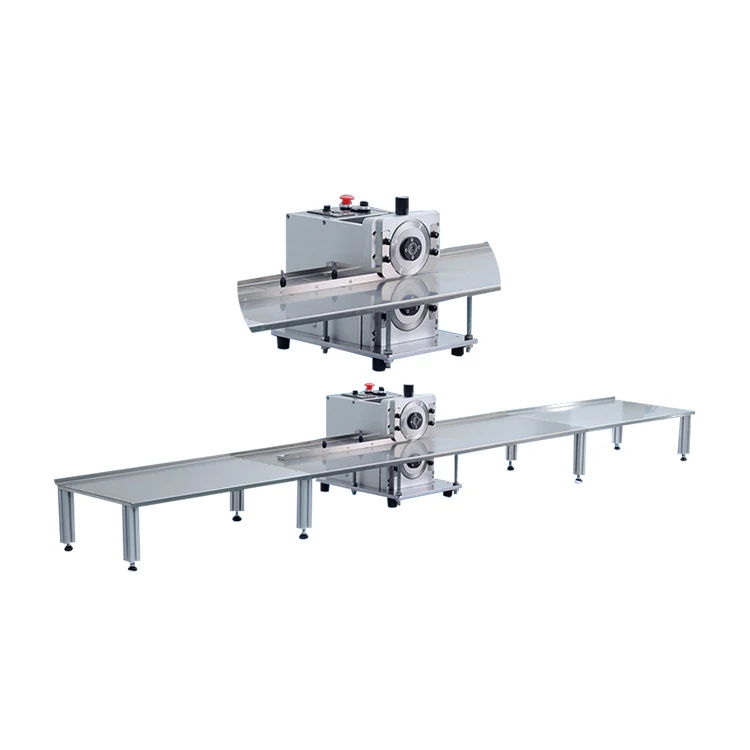

LED Separator

❙ Introduce of LED Separator

High quality PCB V-cut machine, PCB separator, PCB depaneling, for PCBA cutting.

1.Solid and stable,PCBs keep still during the separation,component won`t be damaged.

2.Sliding speed of blade is adjustable manually.

3.Accurate adjustment on Distance between circular blade and straght. blade, due to different depth of V-slot.

4.Compatible to situation that component accross the V-slot.

5.Minimize internal pressure to avoid solder crack.

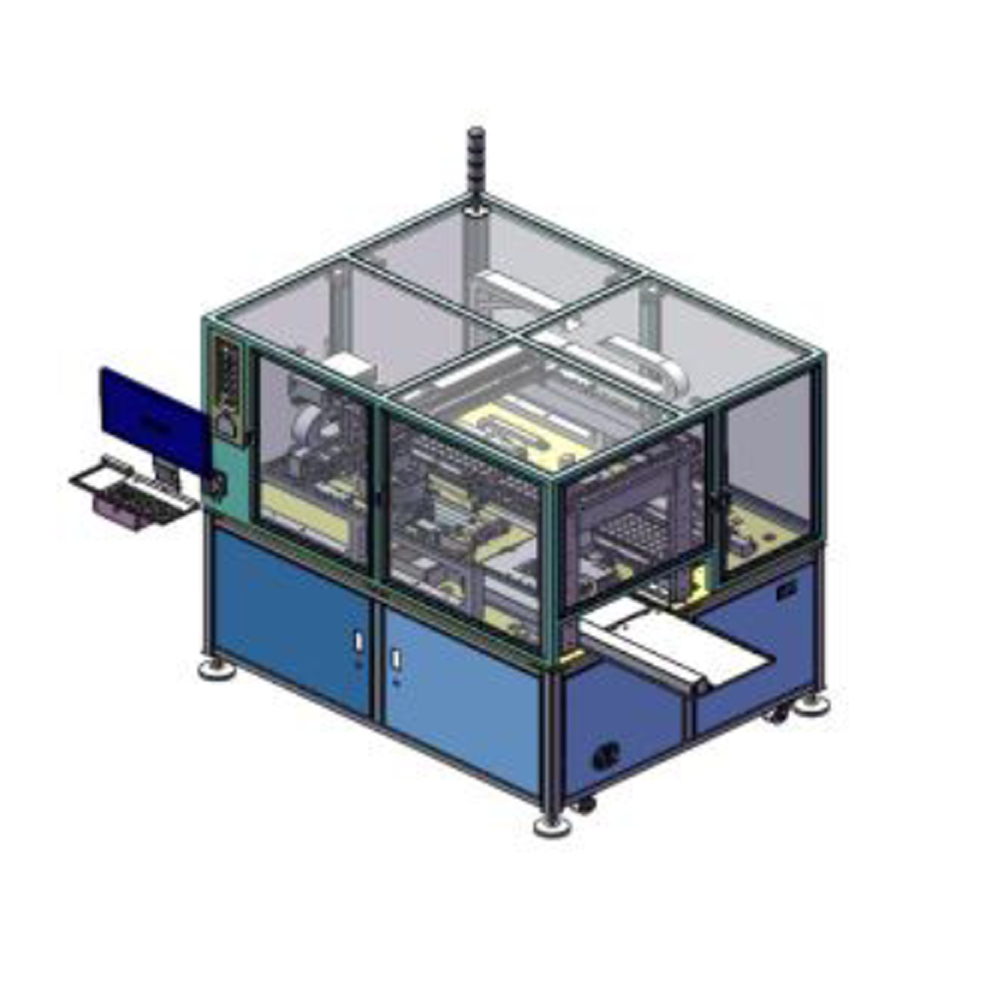

Automatic PCBA Placement Machine

1. Automatic feeding: auto feed the products to be placed in the plate after receiving the signal from the front machine.

2. Automatic code scanning: CCD detects the product size and has the code scanning function at the same time.

3. Automatic pan: CCD guides the suction nozzle to automatically suck OK products to pan.

4. Automatically distinguish NG code: NG products are automatically put into the NG plate, and the NG code and fork plate are put into the defective box.

5. Automatic stacking tray: automatically supply empty trays and stacking OK finished trays full trays.

6. AGV automatically feeds in empty trays and takes away full trays.

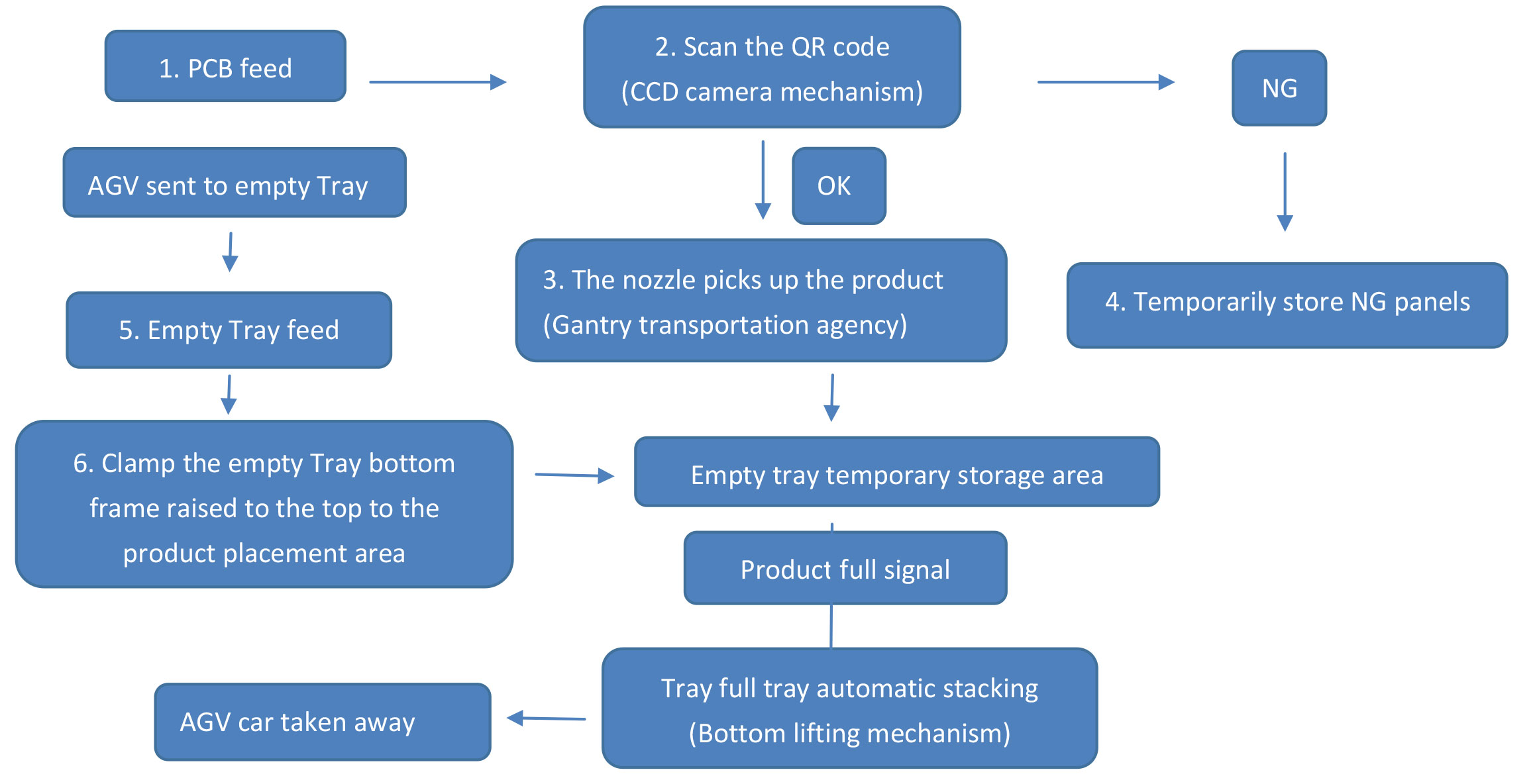

Process:

❙ Specifications of LED Separator

| Model | I.C.T-LS380 |

I.C.T-LS1200 |

I.C.T-LS2400 |

| Dimension |

Host 380*290*380mm Small Platform(Self-equipped) |

Host 380*290*380mm Platform 1200*360*190mm |

Host 380*290*380mm Platform 2400*360*190mm |

| Blade Number |

1 Group(Top 1pcs,Bottom 1pcs) |

||

| Blade Customization |

1 PH AC 220V 50/60Hz (Option:110V to 230V) |

||

| Weight |

31Kg | 31Kg+6Kg |

31Kg+9Kg |

▽ I.C.TAlgeria customer - LED TV SMT Production Line

❙ Company Profile

I.C.T is the SMT machine supplier with professional 25-year-experienced sales and after sales team, providing SMT solutions including pick and place machine, reflow oven, SMT stencil printer, SMT line and wave soldering machine.

Successful Experience:

I.C.T's Customer In 35 Countries Around the World

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT

❙ I.C.T SMT Machine Exhibition

❙ I.C.T Reflow Oven Certificate

❙ I.C.T Global Service

❙ FAQ

SMT Production Line, SMD Production Line, SMT Assembly line, PCB Assembly line, LED Production line, led bulb production line, led display production line, led panel production line, led street lights production line, led strip production line, led tv production line, smartphone smt line, Automatic SMT Assembly line, Semi Automatic SMT Assembly line, electronic production line, JUKI Assembly Line, Samsung Assembly Line, Hanwha Assembly Line, Panasonic Assembly Line, Siemens Assembly Line, FUJI Assembly Line, Yamaha Assembly Line

I.C.T is a manufacturer of SMT machines. It mainly provides customers with SMT production lines including SMT Stencil Printers, Pick and place machines, Reflow Oven, AOI Machine, Wave Soldering Machine and PCB Handling Machine etc.

I.C.T has more than 25 researches on SMT and DIP technology, for the world Customers provide SMT total solutions. There are successful cases of SMT technical team in Asia, Europe, America, Africa, and Australia.

I.C.T provide SMT solutions at various stages according to the different needs of customers. I.C.T is not only a provider of SMT equipment and technology, but also is the customer's escort in the field of SMT and DIP.

Welcome more people to discuss with us about SMT technologies and solutions, please contact us for more information:

Tel: +86 13670124230 (WhatsApp/Skype/WeChat)

Email: info@smt11.com /etasmt@foxmail.com

❙ LED Separator Video