❙ Introduce of PCB Depaneling Machine

High quality PCB depaneling machine, PCBA router machine, desktop PCB router, PCB V-cut machine, PCB separator, LED depaneling, for PCBA cutting.

1. Controlling by micro computer, high stability and accurate positioning.

2. Higher speed can improve cutting result,make the boards away from burr.

3. Blade height slight adjustment in 0 to 2mm,platform height adjustable in 0 to 50mm,to fit PCB of different thickness,and solve the problem of different V-slot depth.

4. Manually Set the position to stop automatically according to specific length of the PCB.

5. PCB width no restriction,max thickness amoung V-slot is 0.25 to 2.0mm.

6. Blades material is the imported high speed steel ,it can be sharpened again when in need. 7. Conveyor belt is optional , conveniently transfer finished PCB out.

8. Stop block can be used for different PCBs, to raise working efficiency.

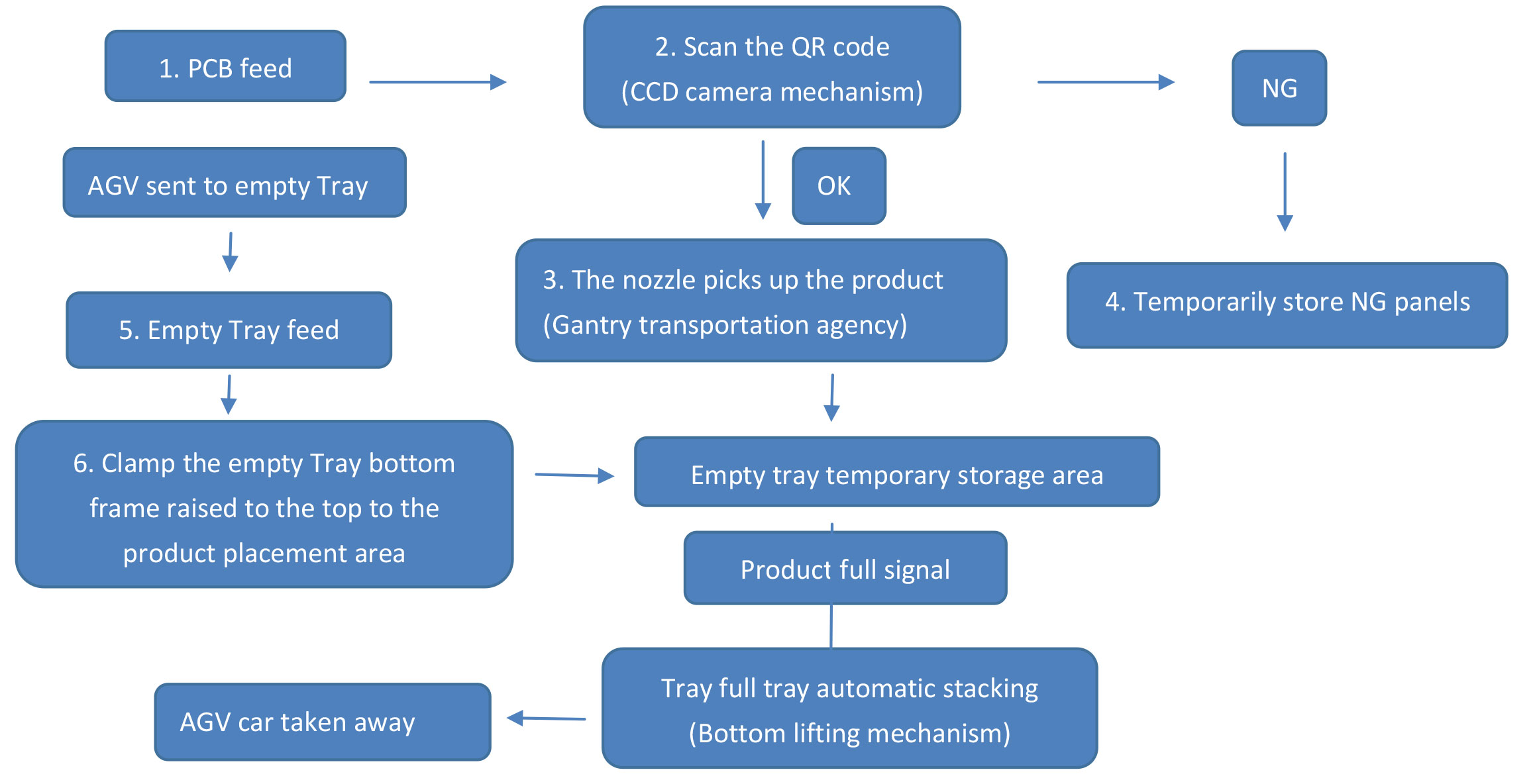

Automatic PCBA Placement Machine

1. Automatic feeding: auto feed the products to be placed in the plate after receiving the signal from the front machine.

2. Automatic code scanning: CCD detects the product size and has the code scanning function at the same time.

3. Automatic pan: CCD guides the suction nozzle to automatically suck OK products to pan.

4. Automatically distinguish NG code: NG products are automatically put into the NG plate, and the NG code and fork plate are put into the defective box.

5. Automatic stacking tray: automatically supply empty trays and stacking OK finished trays full trays.

Process:

❙ Specifications of PCB Depaneling Machine

| Model | I.C.T-MBV360 |

I.C.T-MBV360C(with Conveyor Belt) |

| Dimension |

720*300*440mm |

1000*395*425mm |

| Conveyor Belt Size |

None |

1000*142*127mm |

| PCB Length |

0 to 360mm |

|

| PCB Thickness |

0.3 to 5mm |

|

| Components Height |

2-34mm |

|

| Operation Type |

Manual |

|

| Power |

40Kw |

|

| Power Supply |

1 PH AC 220V 50/60Hz (Option:110V to 230V) |

|

| Weight |

51 Kg | 13 Kg |

▽ Algeria customer - LED TV SMT Production Line

▽ Russia customer - JUKI SMT line

❙ Company Profile

I.C.T is the SMT machine supplier with professional 25-year-experienced sales and after sales team, providing SMT solutions including pick and place machine, reflow oven, SMT stencil printer, SMT line and wave soldering machine.

Successful Experience:

I.C.T's Customer In 35 Countries Around the World

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT

❙ I.C.T SMT Machine Exhibition

❙ I.C.T Reflow Oven Certificate

❙ I.C.T Global Service

❙ FAQ

If you could not find any similar items you want, you may send some photos to us. because our catalog and website haven't included all of our products.

I.C.T is a manufacturer of SMT machines. It mainly provides customers with SMT production lines including SMT Stencil Printers, Pick and place machines, Reflow Oven, AOI Machine, Wave Soldering Machine and PCB Handling Machine etc.

I.C.T has more than 25 researches on SMT and DIP technology, for the world Customers provide SMT total solutions. There are successful cases of SMT technical team in Asia, Europe, America, Africa, and Australia.

I.C.T provide SMT solutions at various stages according to the different needs of customers. I.C.T is not only a provider of SMT equipment and technology, but also is the customer's escort in the field of SMT and DIP.

Welcome more people to discuss with us about SMT technologies and solutions, please contact us for more information:

Tel: +86 13670124230 (WhatsApp/Skype/WeChat)

Email: info@smt11.com /etasmt@foxmail.com

❙ PCB Depaneling Machine Video