1. Application of SMT and DIP Production Line

Today, mobile phones and computers have become essential items in people's daily lives. Android TV boxes have brought a lot of convenience and entertainment to people's lives, and also provided a new possibility for the development of smart homes. The most critical component in these devices is the circuit board, and the manufacturing of circuit boards cannot be separated from the equipment of SMT production line and DIP production line. This article will focus on the application of these two devices in the manufacturing of mobile phones, tablet computer, and Android TV boxes.

2. SMT Process

3. SMT Prodution Line Solution

1 operator to oversee the entire production line, 1 assistant, totaling 2 personnel.

- Automatic PCB Loader

- Full-auto Printing Machine

- 3D SPI

- PCB Conveyor

- 3 sets SMT Pick and Place Machine

- PCB Conveyor

- Reflow Oven (10-12 zones)

- PCB Cooling Conveyor

- On-line SMT AOI

- X-ray Machine

- NG/OK Unloader

In the configuration of SMT production line equipment, it is necessary to consider the compatibility and production efficiency among the various devices. For example, automatic SMT Loader and full-auto PCB Printing Machine should be used together to ensure printing accuracy and stability.

The number of SMT Pick and Place Machine should be determined according to production demand and workload. If the production volume is large, the number of placement machines can be appropriately increased to ensure production progress. When selecting SMT Pick and Place Machine, the size of the components and the accuracy requirements should be considered. For example, high-precision SMT Pick and Place Machine can be used for small components to improve placement accuracy.

Reflow Soldering Oven is an important part of the SMT production line, and it is necessary to ensure that the number of temperature zones and temperature distribution are uniform. The temperature curve can be flexibly adjusted according to different welding process requirements.

Finally, the selection of NG/OK PCB Unloader needs to consider the speed and accuracy of the equipment, as well as the protection level of the PCB.

If you are interested in our SMT Equipment and SMT Solution, please contact us and we will provide you with more detailed information.

4. DIP Process

Plug-in --> Soldering --> Maintenance --> PCB depaneling machine.

On the other hand, the DIP production line is a technology used to manufacture double-sided through-hole printed circuit boards. In the DIP production line, components need to be manually inserted into the predetermined positions on the circuit board and then fixed through soldering techniques. The main equipment in the DIP production line includes a pin-type insertion machine, Wave Soldering Machine, and so on.

In the production of mobile phones, tablets, and Android set-top boxes, the DIP production line is mainly used to manufacture a small number of components on the circuit board, such as sensors, connectors, and so on. Although the DIP production line requires more manual operations, it is still essential in the manufacturing of mobile phones, tablets, and Android set-top boxes because it can meet some process requirements that SMT production lines cannot complete.

5. DIP Prodution Line Solution

Personnel are adjusted according to the product, 8-20 people

We have adopted a DIP production line solution for electronic products such as mobile phones and computers, which includes Auto PCB Loader, Chain PCB Conveyor, Online Selective Wave Soldering Machine, Chain PCB Conveyor, and Automatic PCB Unloader. This production line solution can effectively improve production efficiency and welding accuracy, ensuring product quality and stability.

This fully automatic DIP production equipment can help customers achieve efficient and high-quality PCB board processing, improve production efficiency, and reduce production costs. It can also reduce labor input, reduce human errors, thereby improving the stability and consistency of the production line.

- Automatic PCB Loader

- PCB Conveyor

- On-line Selective Wave Soldering Machine

- PCB Conveyor

- Automatic PCB Unloader

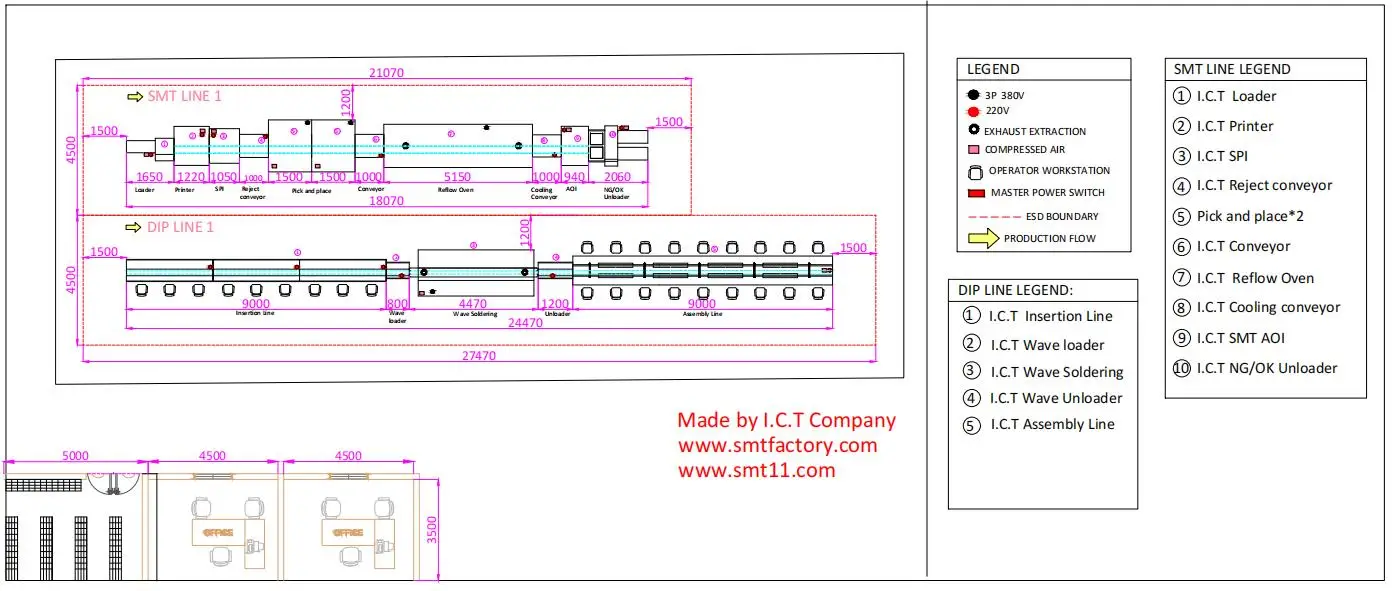

6. SMT Production Line and DIP Line Layout

7. SMT Solution Data

| SMT | Capacity Evaluation | 3 sets pick and place machine; production capacity 55,000-65,000CHIP/H | ||||

| Total Power | 85 KW | Operating Power | 20 KW | |||

| Applicable Product | SMD components within 100pcs, 0201-45mm, max PCB width 350mm |

|||||

| DIP | Capacity Evaluation | Depending on the number of spots, 2-3 seconds per spot. | ||||

| Total Power | 70 KW (2 sets) |

Operating Power | 20 KW (2 sets) | |||

| Applicable Product | Medium and high-end products requirements, Max PCB width 350mm | |||||

| SMT+ DIP |

Workshop Size | L30m x W15m , total area 450 ㎡ | ||||

In summary, both SMT production line and DIP production line equipment are indispensable parts of the manufacturing process for smartphones and tablets. They can achieve high-density placement of components, efficient production, and meet some special process requirements, while also producing high-quality and reliable electronic products. With the continuous development of electronic technology, these production line equipment are also constantly upgraded and improved to meet the ever-changing market demands.

If you are looking for high-quality electronic product SMT production line and solution, please feel free to Contact Us. We will provide the most professional and high-quality services and support.

Show a video for your reference