With the continuous development and progress of technology, more and more consumer electronic products need to be produced through SMT Solution and DIP Solution. These products include routers, controllers, and set-top boxes, which play very important roles in modern society.

The demand for high quality, high efficiency, and high productivity in today's electronic products market continues to increase. In order to meet the market demand, manufacturers must constantly improve their production processes. The close coordination and connection between SMT and DIP processes is one of the necessary conditions to achieve high quality, efficiency, and productivity.

The manufacturing process of products such as routers, controllers, and set-top boxes can be divided into two main stages: the SMT production line and the DIP production line. The SMT production line is mainly responsible for the installation of surface mount components on the circuit board, while the DIP production line is responsible for the installation of through-hole components. The close collaboration and cooperation between the two are key to ensuring product quality and production efficiency.

1. The Difference Between SMT Production line and DIP Production Line

SMT (Surface Mount Technology) production line and DIP (Dual In-line Package) production line are two different production lines in the electronic component manufacturing process.

The SMT production line completes assembly by directly mounting electronic components such as resistors, capacitors, and transistors onto the surface of a printed circuit board (PCB). This technology significantly improves production efficiency and assembly accuracy, while reducing assembly volume and weight. The SMT production line typically includes equipment such as PCB Printing Machine, PCB Pick and Place Machine, PCB Reflow Oven, SMT AOI.

The DIP production line inserts components into pre-drilled holes on the printed circuit board and then performs soldering. This technology used to be the main assembly method in the past but has gradually been replaced in modern electronics manufacturing. The DIP production line typically includes equipment such as an Automatic Insertion Line and a Wave Soldering Machine.

2. SMT Process

3. SMT Line Solution

1 operator to oversee the entire production line, 1 assistant, totaling 2 personnel.

The Full-auto SMT Line involves a variety of equipment, including SMT Magazine Loader, Full-auto SMT Stencil Printer, 3D SPI, SMT Conveyor, 2 sets SMT Chip Mounter, SMT Reflow Soldering Oven (8-10 temperature zones), PCB Cooling Conveyor, Online SMT AOI, and NG/OK Unloader.

- PCB Magazine Loader

- SMT Printer

- 3D SPI

- SMT Conveyor

- 2 sets SMT Pick and Place Machine

- PCB Conveyor

- Reflow Oven (8-10 zones)

- PCB Cooling Conveyor

- In-line SMT AOI

- NG/OK Unloader

These SMT Machines can work efficiently together and produce high-quality routers, controllers, and set-top boxes in a short period of time, ensuring product quality and yield while reducing production costs.

SMT Magazine Loader: responsible for the first step of feeding the circuit board into the production line, can achieve fast and accurate board loading operation.

Full-auto SMT Stencil Printer: evenly applies solder paste on the circuit board to ensure a more secure connection between electronic components.

3D SPI: used to inspect whether the solder paste is evenly applied and to detect any defects, ensuring the quality of the pick-and-place process.

SMT Conveyor: serves as a bridge between various equipment and transfers the circuit board from one equipment to another.

SMT Chip Mounter: precisely place electronic components on the circuit board to achieve the functionality of the circuit board.

SMT Reflow Soldering Oven: heats and cools the solder joints to make the connection between electronic components and the circuit board more secure.

PCB Cooling Conveyor: cools the circuit board after reflow soldering and prepares it for the next step.

Online SMT AOI: uses high-resolution cameras to inspect whether the electronic components on the circuit board are correctly installed and connected, and whether there are any defects.

NG/OK Unloader: categorizes the inspected circuit boards as good or bad for further processing or repair.

4. DIP Process

Plug-in --> Soldering --> Maintenance --> PCB depaneling machine

5. DIP Line Solution

Personnel are adjusted according to the product, 8-20 people

After the surface-mounted components are installed, the PCB needs to enter the DIP production line. In the DIP production line, plug-in components such as IC chips and sockets are inserted into the PCB with the surface-mounted components already installed. Plug-in components are relatively large components that cannot be accurately installed on the PCB using SMT technology, so they need to be manually inserted.

- 9m Insertion Line

- Wave Loader

- Wave Soldering Flux Independent Sprayer

- High-end Lead-free Wave Soldering Machine

- Wave Unloader

- 9m Belt Assembly Line

The DIP production line equipment for routers, controllers, and set-top boxes includes personnel adjustment based on the product, with 8-20 people. This production line is equipped with a series of devices, including a 9-meter PCB Insertion Line, Wave Loader, Wave Soldering Flux Independent Sprayer, a high-end Lead-free Wave Soldering Machine, Wave Uloader, and a 9-meter Bbelt Line.

Among them, the Wave Loader and Wave Unloader are essential equipment in the DIP production line, ensuring high efficiency and continuity throughout the production process. The Wave Soldering Flux Independent Sprayer can spray anti-oxidants during the soldering process to prevent components from being oxidized or otherwise damaged. The high-end lead-free wave soldering machine can achieve higher soldering efficiency and accuracy and is an important piece of equipment in the electronic manufacturing process.

In addition, the 9-meter insertion line and the 9-meter conveyor belt can meet the need for moving equipment during the soldering process, making it convenient for personnel to operate.

In summary, the close coordination and collaboration of SMT and DIP processes are the keys to manufacturing high-quality, high-efficiency, and high-productivity products. When manufacturing electronic products such as routers, controllers, and set-top boxes, the mutual coordination and close connection of SMT production lines and DIP production lines can ensure product quality and production efficiency, thereby meeting the market's demand for high-quality electronic products.

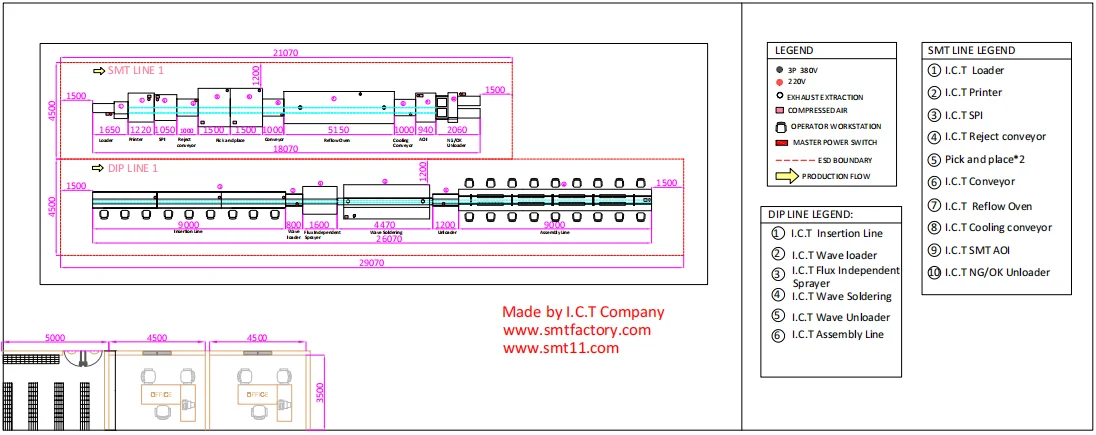

6. SMT Production Line and DIP Line Layout

7. SMT Solution Data

| SMT | Capacity Evaluation | 2 set pick and place machine; production capacity 35000-45000CHIP/H | ||||

| Total Power | 80 KW | Operating Power | 17KW | |||

| Applicable Product | SMD components within 100pcs, 0201-45mm, max PCB width 350mm |

|||||

| DIP | Capacity Evaluation | Calculated based on the number of componens and the operators | ||||

| Total Power | 35.5 KW |

Operating Power | 10.5 KW | |||

| Applicable Product | Low capacity requirements or simple products, Max PCB width 350mm | |||||

| SMT+ DIP |

Workshop Size | L30m x W15m , total area 450 ㎡ | ||||

If you want to quickly invest in the production of power or other similar products, please Contact US immediately. We will provide you with a complete SMT/DIP solution.

Here is the power adapter video for your reference