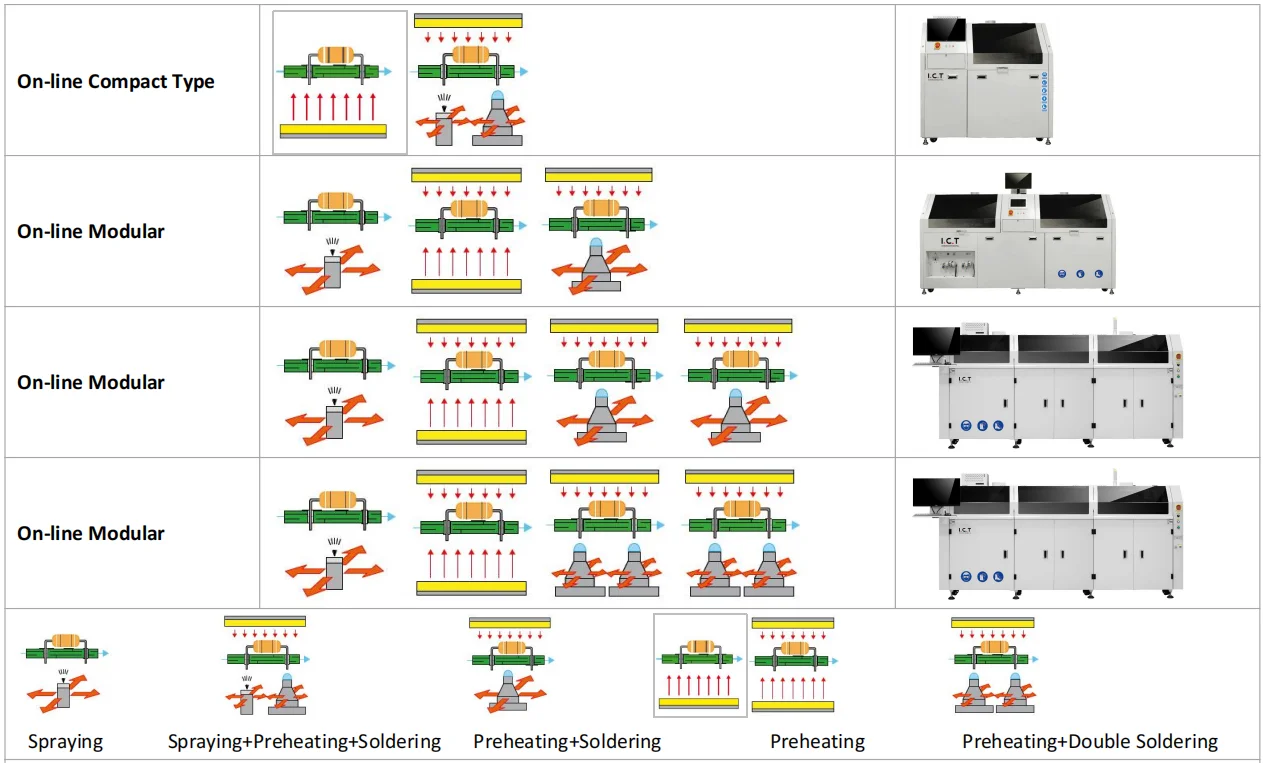

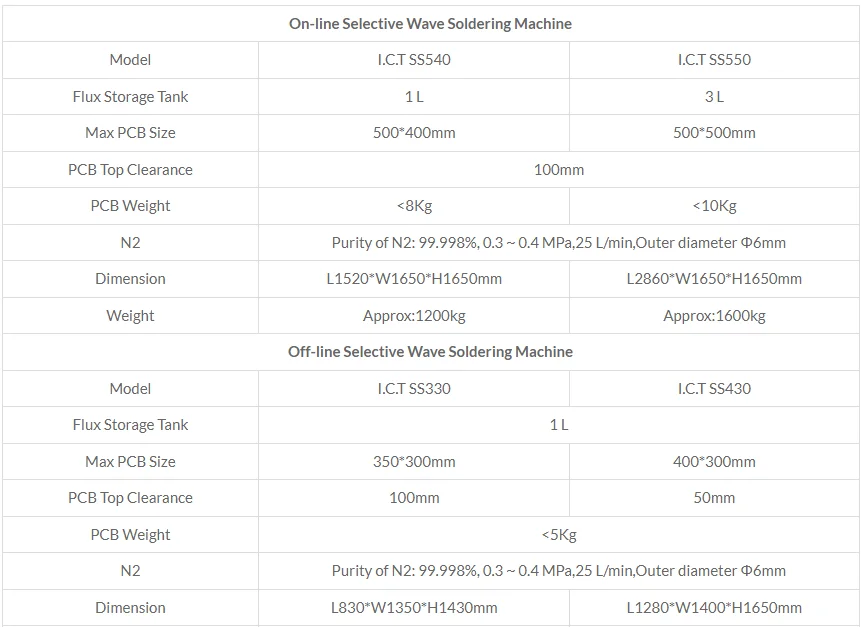

Selective wave soldering is a special form of wave soldering invented to meet the development requirements of through-hole components soldering. It is mainly suitable for the soldering of through-hole components in high-end electronic products. For example: military electronic products, automotive electronics, switching power supply products and other industries which require higher soldering reliability. I.C.T online selective wave soldering is a high performance equipment developed and assembled in China. for higher flexibility or multiwave soldering for high-volume processes.product changes without downtime even in multiwave processes, parallel process due to the separation of fluxing, preheating and soldering, operation of up to two spray heads, up to five lower preheatings with optional upper convection heating,perfect for the connection to assembly stands and periphery, connection to traceability systems for process control.

1. The piezoelectric ceramic jet valve originated in Germany is selected, which is suitable for flux with solid content less than 5%,computer control or manually adjust switch, precise control the spray time, spray speed, economy and environmental protection, digital FLUX flow, spray flow, angle, density, width and other parameters can be recorded.

2. User-friendly design: fault detection (such as heaters abnormal alarm, etc.), regular maintenance reminders,economy functions, emergency manual transmission function and tool-free maintenance, reduce equipment failure rates.

3. Core components: using imported components to ensure long-term stability of equipment operation.

4. It can control the solder quantity, soldering time and solder quantity of each solder spot.

5. Program creation is simple, using pictures or Gerber data to make production program.

6. Nozzle can be selected according to the size of soldering point, and there is no need for fixture to protect non solder parts.

7. PCB pictures can be directly used for path programming. The path starting point, soldering moving speed, empty stroke speed, z-axis height and wave crest height can be set on the computer.

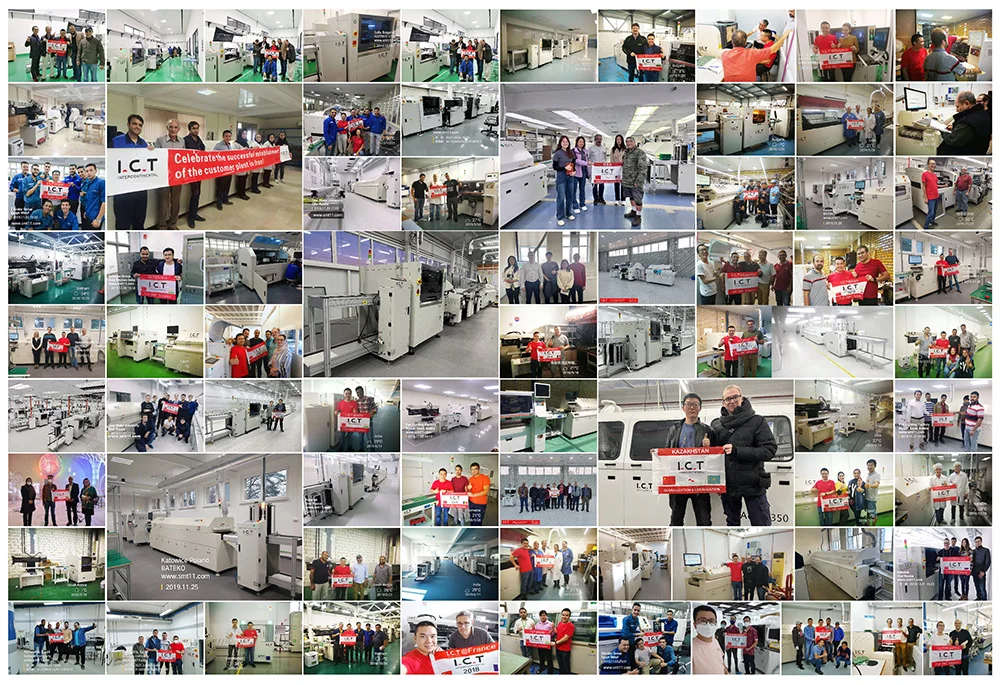

I.C.T is the SMT machine supplier with professional 25-year-experienced sales and after sales team, providing SMT solutions including SMT stencil printer, pick and place machine, reflow oven, SMT line and wave soldering machine.

We also is the partner of JUKI pick and place machine and Hanwha/Samsung pick and place machine, can provide the best SMT technical services and accessories support for JUKI, HANWHA/SAMSUNG, YAMAHA, PANASONIC brands.

Successful Experience:

I.C.T's Customer In 35 Countries Around the World

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT